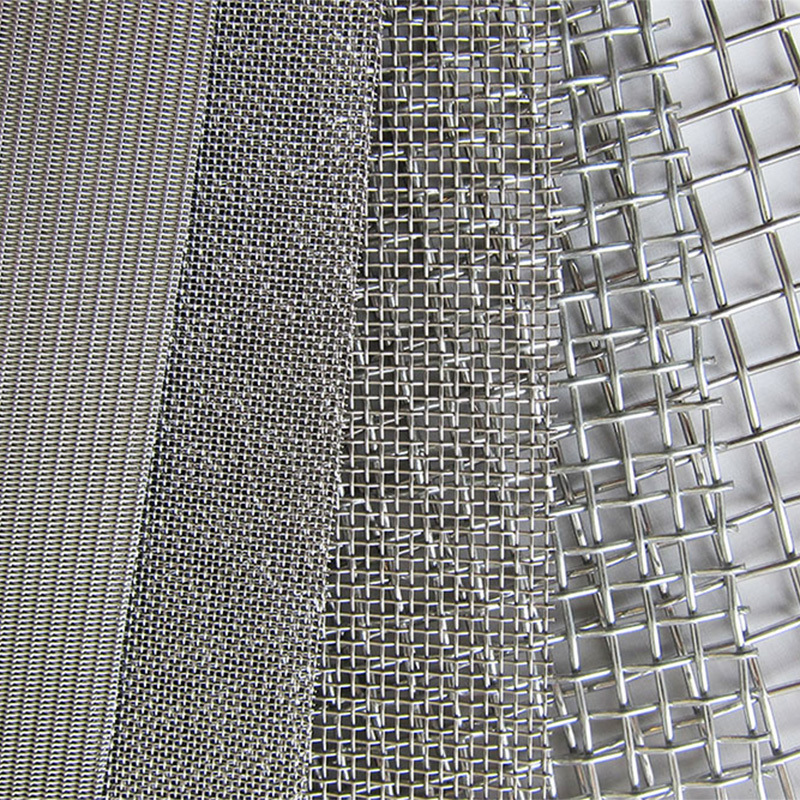

Stable And Fine Filtration Performance Paper Mill Stainless Steel Cylinder Mold Wire Mesh From Manufacturer

Stainless Steel wire mesh used for screening and filtering under acid and alkali environmental conditions, as a mud screen in the petroleum industry, as a screen filter in the chemical and chemical fiber industry, and as a pickling screen in the electroplating industry.

Classification:

Product Description

|

Mesh |

Dimaterial of wire |

Aperture |

Open area |

Net weight (lbs) /100 square feet |

||

|

inch |

mm |

Inch |

mm |

|||

|

1x1 |

0.080 |

2.03 |

0.920 |

23.37 |

84.6 |

41.1 |

|

2X2 |

0.063 |

1.60 |

0.437 |

11.10 |

76.4 |

51.2 |

|

3X3 |

0.054 |

1.37 |

0.279 |

7.09 |

70.1 |

56.7 |

|

4X4 |

0.063 |

1.60 |

0.187 |

4.75 |

56.0 |

104.8 |

|

4X4 |

0.047 |

1.19 |

0.203 |

5.16 |

65.9 |

57.6 |

|

5X5 |

0.041 |

1.04 |

0.159 |

4.04 |

63.2 |

54.9 |

|

6X6 |

0.035 |

0.89 |

0.132 |

3.35 |

62.7 |

48.1 |

|

8X8 |

0.028 |

0.71 |

0.097 |

2.46 |

60.2 |

41.1 |

|

10X10 |

0.025 |

0.64 |

0.075 |

1.91 |

56.3 |

41.2 |

|

10X10 |

0.020 |

0.51 |

0.080 |

2.03 |

64.0 |

26.1 |

|

12X12 |

0.023 |

0.584 |

0.060 |

1.52 |

51.8 |

42.2 |

|

12X12 |

0.020 |

0.508 |

0.063 |

1.60 |

57.2 |

31.6 |

|

14X14 |

0.023 |

0.584 |

0.048 |

1.22 |

45.2 |

49.8 |

|

14X14 |

0.020 |

0.508 |

0.051 |

1.30 |

51.0 |

37.2 |

|

16X16 |

0.018 |

0.457 |

0.0445 |

1.13 |

50.7 |

34.5 |

|

18X18 |

0.017 |

0.432 |

0.0386 |

0.98 |

48.3 |

34.8 |

|

20X20 |

0.020 |

0.508 |

0.0300 |

0.76 |

36.0 |

55.2 |

|

20X20 |

0.016 |

0.406 |

0.0340 |

0.86 |

46.2 |

34.4 |

|

24X24 |

0.014 |

0.356 |

0.0277 |

0.70 |

44.2 |

31.8 |

|

30X30 |

0.013 |

0.330 |

0.0203 |

0.52 |

37.1 |

34.8 |

|

30X30 |

0.012 |

0.305 |

0.0213 |

0.54 |

40.8 |

29.4 |

|

30X30 |

0.009 |

0.229 |

0.0243 |

0.62 |

53.1 |

16.1 |

|

35X35 |

0.011 |

0.279 |

0.0176 |

0.45 |

37.9 |

29.0 |

|

40X40 |

0.010 |

0.254 |

0.0150 |

0.38 |

36.0 |

27.6 |

|

50X50 |

0.009 |

0.229 |

0.0110 |

0.28 |

30.3 |

28.4 |

|

50X50 |

0.008 |

0.203 |

0.0120 |

0.31 |

36.0 |

22.1 |

|

60X60 |

0.0075 |

0.191 |

0.0092 |

0.23 |

30.5 |

23.7 |

|

60X60 |

0.007 |

0.178 |

0.0097 |

0.25 |

33.9 |

20.4 |

|

70X70 |

0.0065 |

0.165 |

0.0078 |

0.20 |

29.8 |

20.8 |

|

80X80 |

0.0065 |

0.165 |

0.0060 |

0.15 |

23.0 |

23.2 |

|

80X80 |

0.0055 |

0.140 |

0.0070 |

0.18 |

31.4 |

16.9 |

|

90X90 |

0.005 |

0.127 |

0.0061 |

0.16 |

30.1 |

15.8 |

|

100X100 |

0.0045 |

0.114 |

0.0055 |

0.14 |

30.3 |

14.2 |

|

100X100 |

0.004 |

0.102 |

0.0060 |

0.15 |

36.0 |

11.0 |

|

100X100 |

0.0035 |

0.089 |

0.0065 |

0.17 |

42.3 |

8.3 |

|

110X110 |

0.0040 |

0.1016 |

0.0051 |

0.1295 |

30.7 |

12.4 |

|

120X120 |

0.0037 |

0.0940 |

0.0064 |

0.1168 |

30.7 |

11.6 |

|

150X150 |

0.0026 |

0.0660 |

0.0041 |

0.1041 |

37.4 |

7.1 |

|

160X160 |

0.0025 |

0.0635 |

0.0038 |

0.0965 |

36.4 |

5.94 |

|

180X180 |

0.0023 |

0.0584 |

0.0033 |

0.0838 |

34.7 |

6.7 |

|

200X200 |

0.0021 |

0.0533 |

0.0029 |

0.0737 |

33.6 |

6.2 |

|

250X250 |

0.0016 |

0.0406 |

0.0024 |

0.0610 |

36.0 |

4.4 |

|

270X270 |

0.0016 |

0.0406 |

0.0021 |

0.0533 |

32.2 |

4.7 |

|

300X300 |

0.0051 |

0.0381 |

0.0018 |

0.0457 |

29.7 |

3.04 |

|

325X325 |

0.0014 |

0.0356 |

0.0017 |

0.0432 |

30.0 |

4.40 |

|

400X400 |

0.0010 |

0.0254 |

0.0015 |

0.370 |

36.0 |

3.3 |

|

500X500 |

0.0010 |

0.0254 |

0.0010 |

0.0254 |

25.0 |

3.8 |

|

635X635 |

0.0008 |

0.0203 |

0.0008 |

0.0203 |

25.0 |

2.63 |

Please contact me to get more models and details.

Produce Process

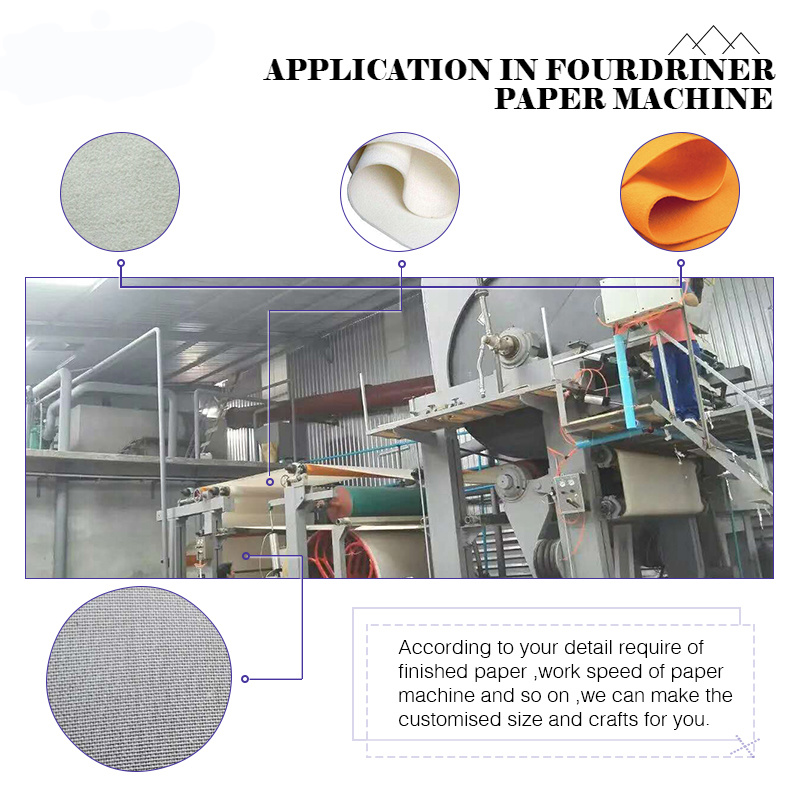

Application

Packaging & Delivery

Company Introduction