Everything You Need to Know about Paper Edge Board Machines

Release time:

2024-05-30

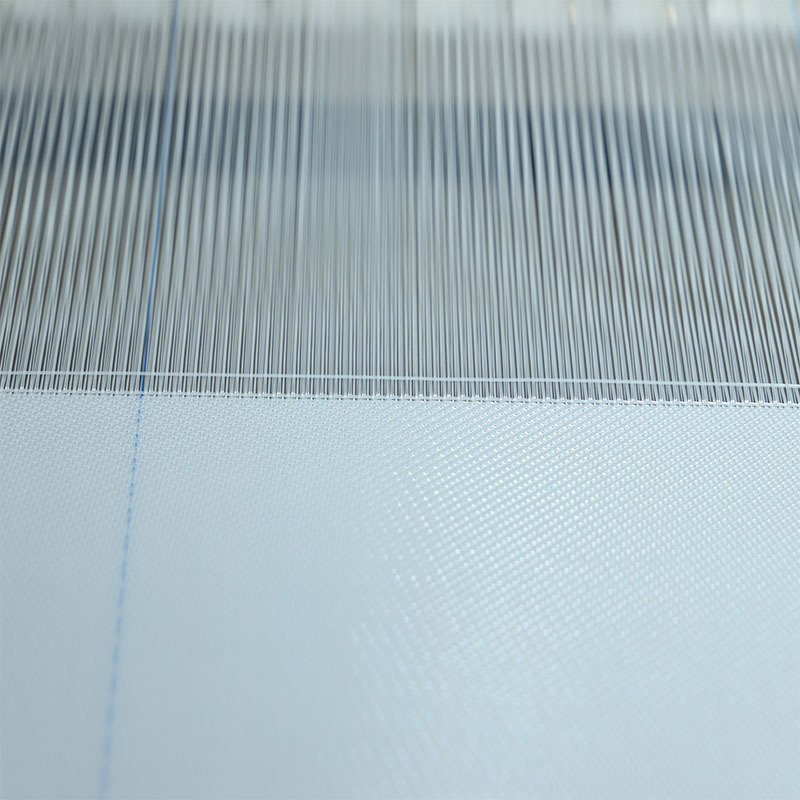

Paper edge board machines are essential equipment in the paper manufacturing industry. These machines are used to produce edge protectors that are applied to the edges of paper sheets or rolls to provide support and protection during transportation and storage. The process of making paper edge boards involves feeding a continuous web of paper through the machine, where it is cut, folded, and glue

The process of making paper edge boards involves feeding a continuous web of paper through the machine, where it is cut, folded, and glued to create sturdy and reliable edge protectors. These protectors are then ready to be used in various packaging applications, such as protecting palletized goods or reinforcing cardboard boxes.

One of the key benefits of using paper edge board machines is their ability to increase the strength and stability of paper products, reducing the risk of damage during handling and shipping. By adding edge protectors, manufacturers can ensure that their products arrive at their destination in perfect condition, improving customer satisfaction and reducing the likelihood of returns or complaints.

In addition to enhancing the durability of paper products, edge boards also contribute to sustainability efforts by reducing the amount of packaging material needed and minimizing waste. By using edge protectors, manufacturers can optimize their packaging processes and reduce their environmental impact, making them a valuable asset for businesses looking to improve their sustainability practices.

Overall, paper edge board machines play a crucial role in the paper manufacturing industry by providing a cost-effective and efficient solution for protecting and strengthening paper products. By investing in these machines, manufacturers can improve the quality of their packaging, reduce the risk of damage in transit, and contribute to a more sustainable supply chain.

Qinyang NH Paper Machinery Industrial Group Co., Ltd.

WhatsApp/WeChat:Cathy Wang 0086-15721522521

WhatsApp/WeChat:Ailsa Zhao 0086-18300605679

ADD: Jianshe Road(South),Qinyang City Henan Province,China

Cathy Wang

Alisa Zhao

TikTok

Copyright©Qinyang City Nianhai Net Industry Co., Ltd.

SAF Coolest v1.3.1.1 设置面板 AIVSX-ZBBO-FQSEE-ZAS

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page