Urban sugar ceramic slaughter printing and dyeing factory sewage treatment mesh belt

Sewage treatment mesh belt is used for: urban sewage treatment mesh belt, sugar factory sewage treatment mesh belt, cassava residue treatment mesh belt, ceramic factory sewage treatment mesh belt, slaughterhouse sewage treatment mesh belt, tailings sewage treatment mesh belt, printing and dyeing factory sewage Handle the mesh belt. The sewage treatment mesh belt has the characteristics of breathable, permeable and impermeable material (sludge), strong acid resistance and strong alkali resistance. The mesh design makes the filter cake easy to peel off and easy to clean. Mainly used with belt filter press, rubber belt vacuum filter, horizontal belt vacuum filter

Classification:

Product Description

|

Model |

Diameter mm |

Density |

Strength (N/cm) |

Air permeability (m3/h) |

||

|

Warp |

Weft |

Warp |

Weft |

|||

|

16903 |

0.7 |

0.9 |

16 |

5.33 |

≥2200 |

7894±500 |

|

22903 |

0.5 |

0.9 |

22 |

5.33 |

≥2000 |

6800±500 |

|

26806 |

0.5 |

0.8 |

27 |

8.5 |

≥2100 |

5120±500 |

|

15905 |

0.9 |

0.9 |

17 |

4.8 |

≥4500 |

6741±500 |

|

151105 |

0.9 |

1.1 |

16 |

4.8 |

≥5000 |

6749±500 |

|

121104 |

0.9 |

1.1 |

12 |

3.8 |

≥3600 |

8610±500 |

Please contact me to get more details and models.

Application

Polyester sludge dewatering mesh with 22903 16903 15905 151105 spiral pressure filter 151105N series, according to the customer’s different use environment and equipment size, our mesh belt is widely used in ceramic polishing sewage treatment, magnet concentrator, steel plant sewage For the treatment of gold mines, urban sewage treatment, sand washing plant sewage treatment, slaughter, printing and dyeing sewage treatment and other industries, the 151105n mesh belt is a mesh belt developed for the application of heavy-duty filter press on the dry tailings discharge. It uses PET/PP The characteristics of the mixed woven mesh belt are based on the characteristics of the general sludge dewatering network: high wear resistance, high tensile strength, good flexibility, etc., and are well received by customers!

Sludge dewatering mesh belt and polyester sludge dewatering mesh belt are mainly used for sludge treatment and solid-liquid separation (such as cassava residue treatment) on papermaking, printing and dyeing, textile, slaughter, urban sewage and dry tailings , Sugar mills, juice presses, etc.), according to the different types of materials processed in each industry, the classification of sludge includes organic activated sludge and inorganic sludge, organic sludge such as leather, printing and dyeing, and slaughter. This kind of viscosity is relatively large and it is not easy to peel off. When selecting the mesh, the belt filter press should choose the segmented sludge dewatering net, such as: 5 healds and 8 healds with herringbone patterns. The advantage is: the smooth surface of the net is good for peeling and filtering. Fast water effect, strong stability, good fatigue and wear resistance .

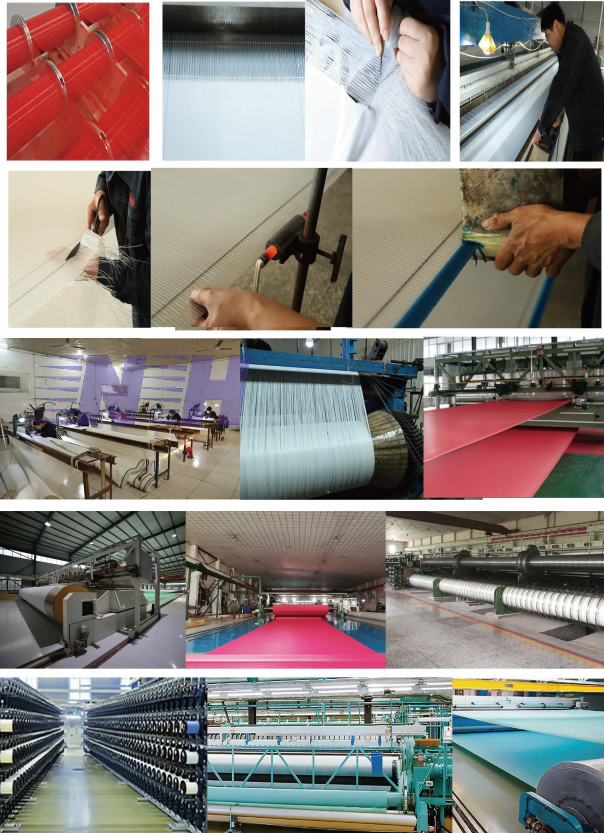

Production Process

Service

Pre-Sales Service

1. Proposing the most suitable scheme and equipment for our clients.

2. Designing and fabricating targeted products according to the special requirements of clients.

3. Training periodically high qualified service technician.

After-Sales Service

1.Field installation, commissioning and training

2.Video technical support

3.Field maintenance and repair service

4.Online support

Packaging and delivery

Company Introduction

NH Paper Machinery Industrial Group is a leading professional paper machine manufacturer in China, which specializes in making machine, paper making machine and all kinds of paper machine components manufacturing. Based on the development of local market ,we are growing to professional paper mill solution provider. NH Paper Machinery Industrial Group fully implement the guideline in business-"survival depends on quality and service ,market rely on price and brand."

Our main products are a full set of new and second hand paper making equipment with a maximum net with of 6000 mm and a working speed of 700 m/min.It mainly includes a packaging paper production line with an annual output of 200,000-200,000 tons, a cultural paper production line with an annual output of 1-10 million tons, a tissue paper production line with an annual output of 20,000 tons and various special paper production lines.

Look forward to hearing from you sooner and establishing a long friendly business relationship with you . We promise we will do our best to help you .Besides ,welcome you to visit our factory at anytime.

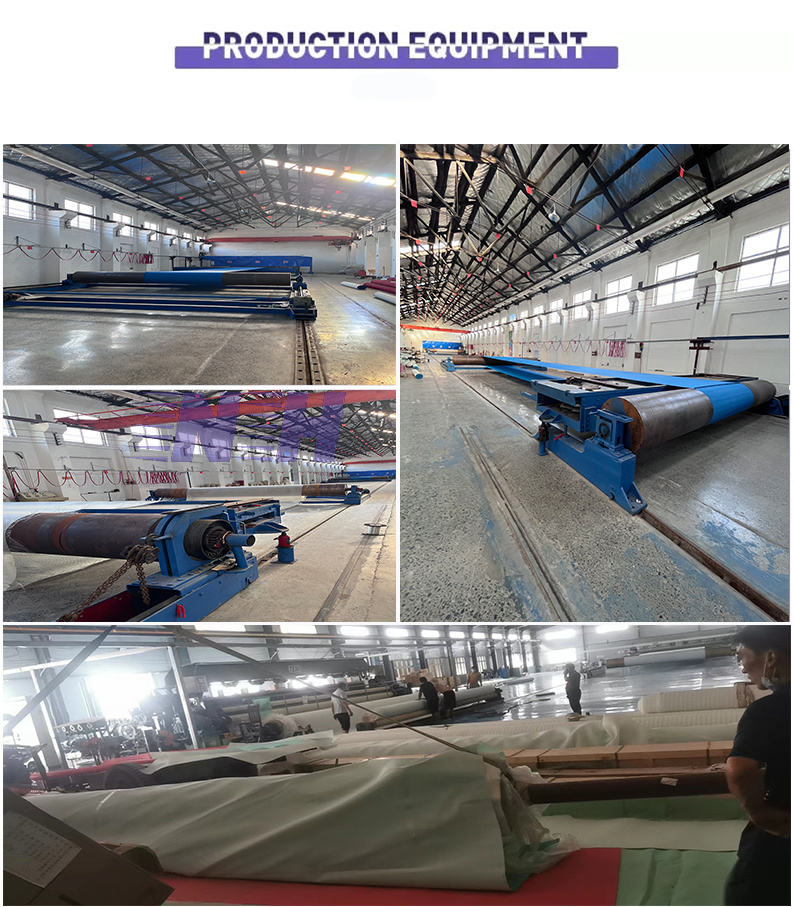

According to the process, divided into different workshop .With strict quality control system to ensure the finished product quality .

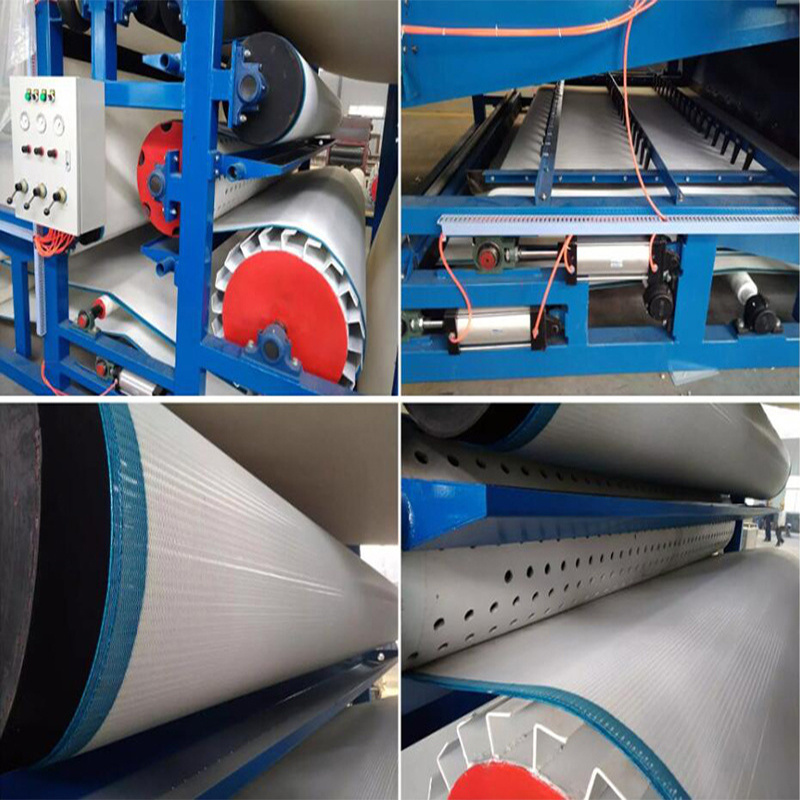

Part of production equipment for you reference .

1. Special oil heat setting process,increase more than 40% service life.

2. Shuttless weaving process to extend the life of the monofilament.

3. Precise laser spot welding interface of stainless steel wire mesh to ensure the breathability and flatness of stainless steel wire mesh.

We have stable cooperation relationship with our clients.

Key words:

Related Products

Welcome your product consultation

Qinyang NH Paper Machinery Industrial Group Co., Ltd.

WhatsApp/WeChat:Cathy Wang 0086-15721522521

WhatsApp/WeChat:Ailsa Zhao 0086-18300605679

ADD: Jianshe Road(South),Qinyang City Henan Province,China

Cathy Wang

Alisa Zhao

TikTok

Copyright©Qinyang City Nianhai Net Industry Co., Ltd.

SAF Coolest v1.3.1.1 设置面板 AIVSX-ZBBO-FQSEE-ZAS

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page