Low Consistency Cleaner

Low Consistency Slag Cleaner utilizes the difference in specific gravity between the fibers and the impurities to separate the heavy impurities from the pulp to achieve the purpose of purifying the pulp. The equipment can be used in a wide range of applications, both for the rough cleaning of high-energy pulp and for the selective purification of low-concentration pulp before the paper machine. It can be used in the production of chemical pulp, semi-chemical pulp, and in the production of mechanical pulp waste pulp. It is widely used in the production of boxboard paper, corrugated paper, cultural paper, newsprint and toilet paper, especially for purifying waste paper pulp and semi-chemical method. The straw effect is better .

Advantage

A . Split structure

The desander is a split structure, the whole desander can be divided into 3~4 sections, which is easy to disassemble and replace

B. Different slagging methods

The heavy-weight cleaner can choose different slagging methods according to the different needs of users: pressure type slagging or open type slagging to adapt to the user's working environment.

C. Ceramic wear-resistant slag removal nozzle

The neck of all centrifugal cleaners is the place where the tangential speed is the highest and the wear is the most concentrated. The lower part of the cone of the heavy-weight cleaner adopts ceramic wear-resistant nozzles, which not only ensures a stable discharge rate and prolongs the service life. The company provides ceramic slag removal nozzles in different forms and specifications according to different slagging methods and different needs of users.

Parameter

|

Model

|

ZSC-Ⅰ

|

ZSC-Ⅱ

|

ZSC-Ⅲ

|

ZSC-Ⅳ

|

ZSC-V

|

ZSC-Ⅵ

|

ZSC-Ⅶ

|

ZSC-Ⅷ

|

ZSC-Ⅸ

|

ZSC-Ⅹ

|

|

Capacity(t/d)

|

10-20

|

20-40

|

40-60

|

50-70

|

60-80

|

80-110

|

100-130

|

130-200

|

200-280

|

300-400

|

|

Slurry consistency

(%)

|

0.8-5

|

|

Pressure of inflow pulp (mpa)

|

0.15-0.35

|

|

Slurry pressure (mpa)

|

0.1-0.25

|

|

Flush water pressure(mpa)

|

Pressure of inflow pulp+0.02MPa

|

Product Detail

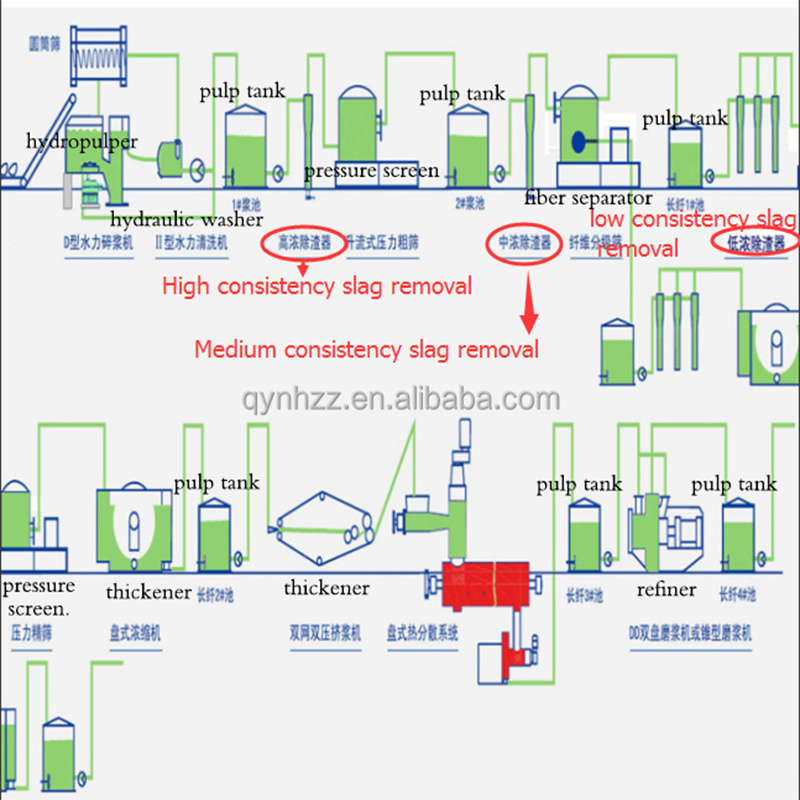

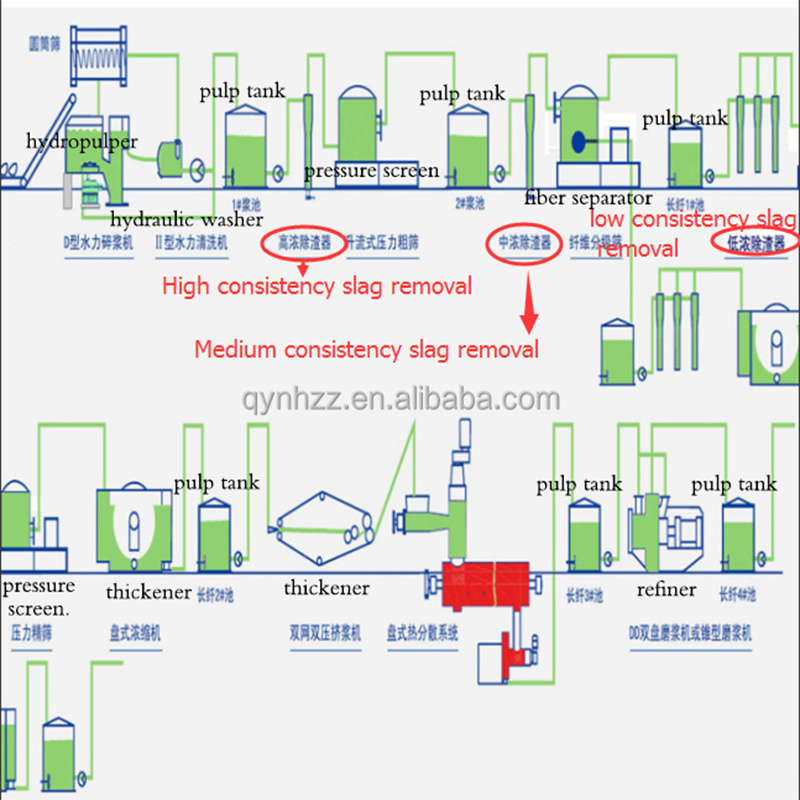

Low consistency slag removal equipment

Low and medium consistency slag removal equipment are ideal equipment that utilize the theory of centrifugal to get rid light & heavy in thick liquid material such as mixed sticky poeder ,sandstone ,paraffin wax ,heat melt glue ,plastics pieces ,dust ,foam , gas ,scrap iron and printing ink particle etc .

Low cone of slag removal equipment

There are plastic and stainless steel material.

Application

Packing & Delivery

Company Introduction

NH Paper Machinery Industrial Group is a leading professional paper machine manufacturer in China, which specializes in making machine, paper making machine and all kinds of paper machine components manufacturing. Based on the development of local market ,we are growing to professional paper mill solution provider. NH Paper Machinery Industrial Group fully implement the guideline in business-"survival depends on quality and service ,market rely on price and brand."

Our main products are a full set of new and second hand paper making equipment with a maximum net with of 6000mm and a working speed of 700m/min.It mainly includes a packaging paper production line with an annual output of 200,000-200,000 tons, a cultural paper production line with an annual output of 1-10 million tons, a tissue paper production line with an annual output of 20,000 tons and various special paper production lines.

Look forward to hearing from you sooner and establishing a long friendly business relationship with you . We promise we will do our best to help you .Besides ,welcome you to visit our factory at anytime.

According to the process, divided into different workshop .With strict quality control system to ensure the finished product quality .

We have stable cooperation relationship with our clients.