Small type paper making machine for glassine cylinder mould for toilet paper with dryer mould for cellophane

Cheap small paper making machinery and china small paper making machinery are cost-effective options for paper production, providing efficient solutions for small-scale operations.

Classification:

Product Description

|

Output paper |

High strength corrugated paper |

Corrugated paper core |

Template/newsprint paper |

|---|---|---|---|

|

Net paper width |

1575-5600mm |

2400-5600mm |

2400-3880mm |

|

Gram weight of finished paper |

80-130g/m2 |

55-80g/m2 |

50-80g/m2 |

|

Production capacity |

400T/D |

200T/D |

150T/D |

|

Design speed |

500m/min |

350m/min |

400m/min |

|

Work speed |

450-500m/min |

300-350m/min |

350-400m/min |

|

Center distance |

2400-7000mm |

3600-7000mm |

3600-5000mm |

|

Transmission form |

Frenquency control |

Frenquency control |

Frenquency control |

|

Layout form |

Monolayer layout |

Monolayer layout |

Monolayer layout |

|

Auxiliary equipment |

Closed gas hood |

/ |

/ |

|

Toilet paper (Vacuum mould/crescent forming device) |

Testliner board/high-strength corrugated paper |

Ordinary corrugated paper |

Coated whiteboard paper |

|

1092-3600mm |

2400-5600mm |

2400-5600mm |

1760-5600mm |

|

12-20g/m2 |

80-180g/m2 |

65-110g/m2 |

180-400g/m2 |

|

50T/D |

400T/D |

300T/D |

550T/D |

|

800m/min |

500m/min |

600m/min |

400m/min |

|

700-750m/min |

450-500m/min |

500-550m/min |

300-350m/min |

|

1900-4800mm |

3600-7000mm |

3600-7000mm |

2800-7000m/min |

|

Frenquency control |

Frenquency control |

Frenquency control |

Frenquency control |

|

Monolayer layout |

Monolayer layout |

1.5 layout |

Monolayer layout |

|

Breathing gas hood |

Closed gas hood |

Closed gas hood |

Closed gas hood |

Product Detail

Main frame of direct factory selling small waste paper recycling machinery for tissue toilet paper:

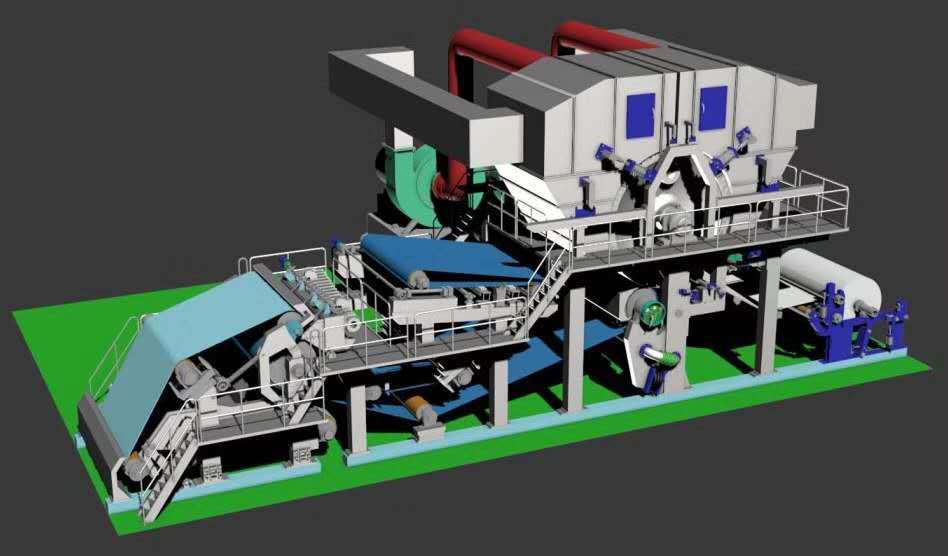

There are several different paper machine types for you to choose, such as cylinder type, fourdrinier type, inverformer type, etc. Actually, most economic one is cylinder type but its stablity is lower than other two types. Here I take fourdrinier type for an example for your reference.

1. Fourdrinier wire part

Fourdrinier wire part including wire board, chest roller and landing gear, dewatering component set, guide roller, scraper, high/low pressure spray pipe, flushing sprinkler, tensioner, corrector, white water pan, drive roller, vacuum Volt roller, fixed edge water needle, water jet needle, walking bracket and so on. Fourdrinier wire parts change clothing adopts cantilever type.

2. Press part

It consists of a large roll diameter composite press and a large roll diameter. There are two nips. The press section is equipped with a guide roller, a corrector, a tensioner, a high and low pressure water spray pipe, a suction box, a scraper, a water receiving tray, a walking platform and a roll changing trolley. The press section roller bearings are grease lubricated.

3. Dryer part

The surface of the dryer cylinder is chrome-plated, the thickness of the chrome plate is 0.1mm, the surface hardness of the dryer cylinder is uniform, and the unprocessed surface is smooth and tidy. The drying section is driven by a closed gear box.

4. Pulping part

Including all of the equipment and auxiliary equipment.

5. Winding part: winding machine

6. Rewinding part: rewinding machine

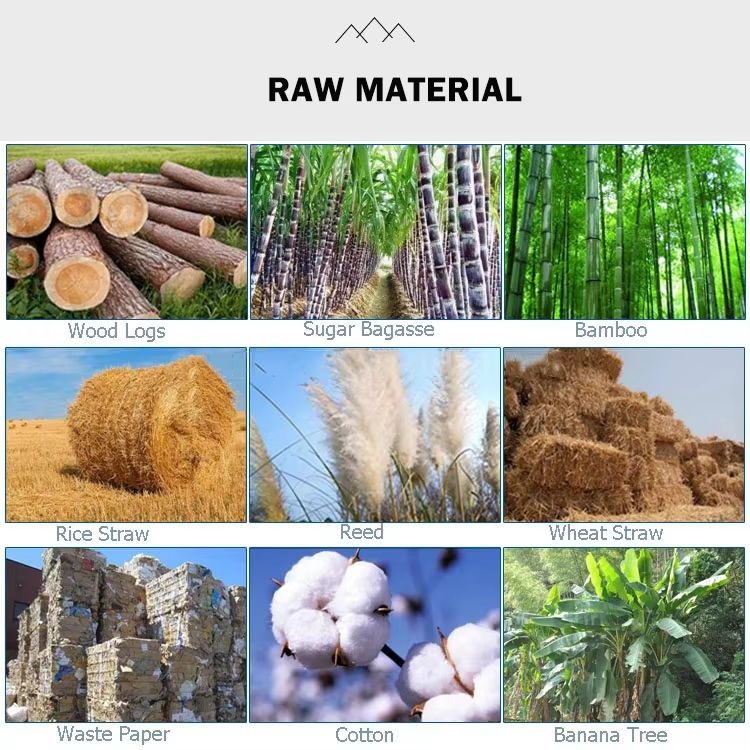

Raw Material & Application

Packing & Delivery

About Us

NH Paper Machinery Industrial Group is a leading professional paper machine manufacturer in China, which specializes in making machine, paper making machine and all kinds of paper machine components manufacturing. Based on the development of local market ,we are growing to professional paper mill solution provider. NH Paper Machinery Industrial Group fully implement the guideline in business-"survival depends on quality and service ,market rely on price and brand."

Our main products are a full set of new and second hand paper making equipment with a maximum net with of 6000mm and a working speed of 700m/min.It mainly includes a packaging paper production line with an annual output of 200,000-200,000 tons, a cultural paper production line with an annual output of 1-10 million tons, a tissue paper production line with an annual output of 20,000 tons and various special paper production lines.

Look forward to hearing from you sooner and establishing a long friendly business relationship with you . We promise we will do our best to help you .Besides ,welcome you to visit our factory at anytime.

Accroding to the process, divided into different workshop .With strict quality control system to ensure the finished product quality.

According to the process, divided into different workshop .With strict quality control system to ensure the finished product quality .

Our factory have over 30 years history , have developed good and stable relationship with customers for all over the world based on our product quality ,worker’s service and best price .

The paper making machine is an advanced and essential piece of equipment in the paper production industry. It is designed to transform raw materials such as wood pulp, recycled paper, or other fibrous substances into high-quality paper.

This machine incorporates state-of-the-art technology and precision engineering to ensure efficient and consistent paper production. It is capable of handling large volumes of raw materials and converting them into sheets of paper with uniform thickness, smoothness, and strength.

With its automated processes and adjustable settings, the paper making machine offers flexibility in producing different types of paper, including various grades, sizes, and finishes. It helps to meet the diverse needs of the market, whether for printing, packaging, or other applications.

The machine is also built to minimize waste and maximize resource utilization, making it an environmentally friendly option. It operates with high reliability and durability, reducing downtime and maintenance costs.

In summary, the paper making machine is a crucial tool for the paper industry, enabling the production of high-quality paper products efficiently and reliably, and playing a significant role in meeting the ever-growing demand for paper in different sectors.

Key words:

Related Products

Welcome your product consultation

Qinyang NH Paper Machinery Industrial Group Co., Ltd.

WhatsApp/WeChat:Cathy Wang 0086-15721522521

WhatsApp/WeChat:Ailsa Zhao 0086-18300605679

ADD: Jianshe Road(South),Qinyang City Henan Province,China

Cathy Wang

Alisa Zhao

TikTok

Copyright©Qinyang City Nianhai Net Industry Co., Ltd.

SAF Coolest v1.3.1.1 设置面板 AIVSX-ZBBO-FQSEE-ZAS

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page