2.5 layers Polyester Forming Fabric Wire Mesh

3 layers polyester forming fabric for toilet paper making machine cylinder mould pick up fabric mesh good air permeability, according to the different weave ways used for different speeds of paper machine, including: single layer forming mesh belt, one and half layers forming mesh belt, two layers forming mesh belt, two and half layers forming mesh belt, three layers forming mesh belt.

Advantage

1. High stiffness

2. Good paper support and paper guiding effect

3. Run smoothly

4. High air permeability

5. Strong wear resistance

6. Lateral dimensional stability

Product Superiority

1. Good threading and dehydration

2. Fiber support index and retention are greatly improved

3. Long operating life

4. Dimensionally stable

5. Good page characteristics

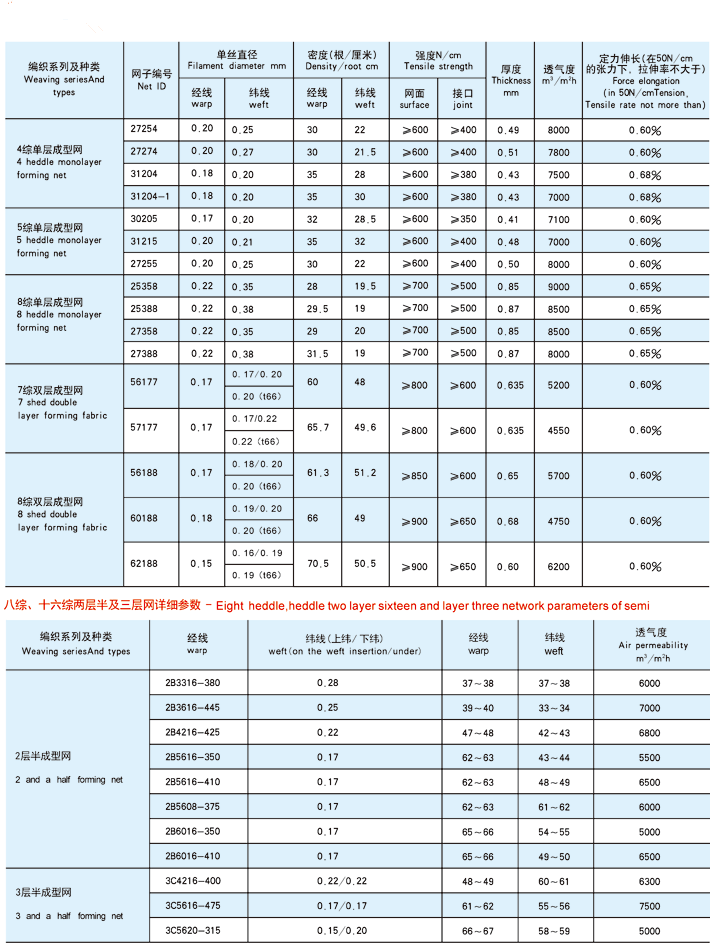

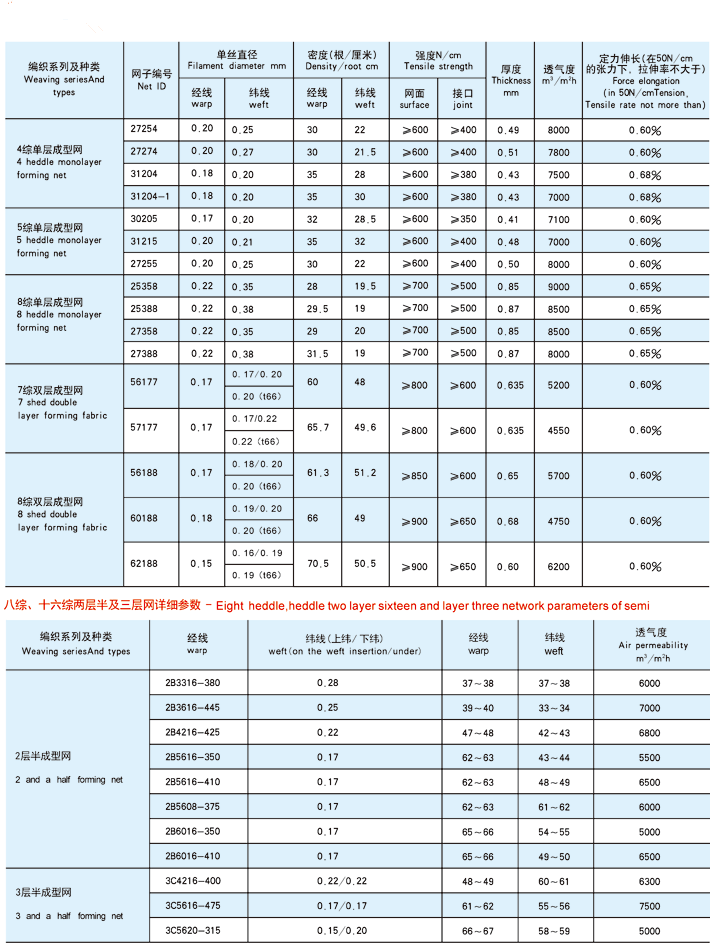

Parameter

Please contact me to get more models and details!

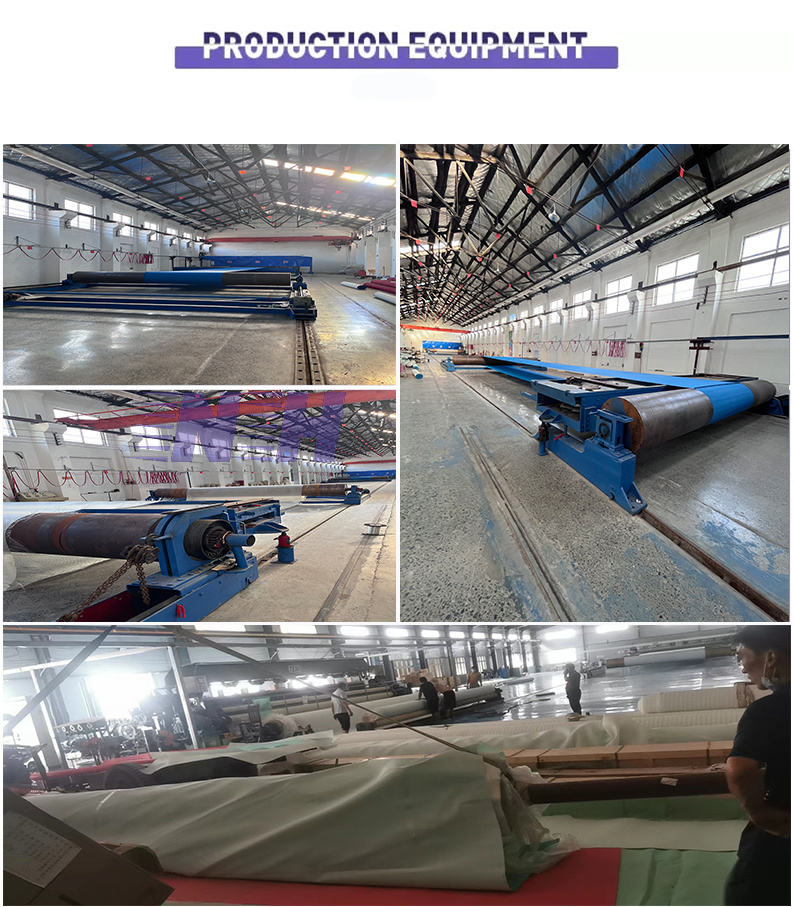

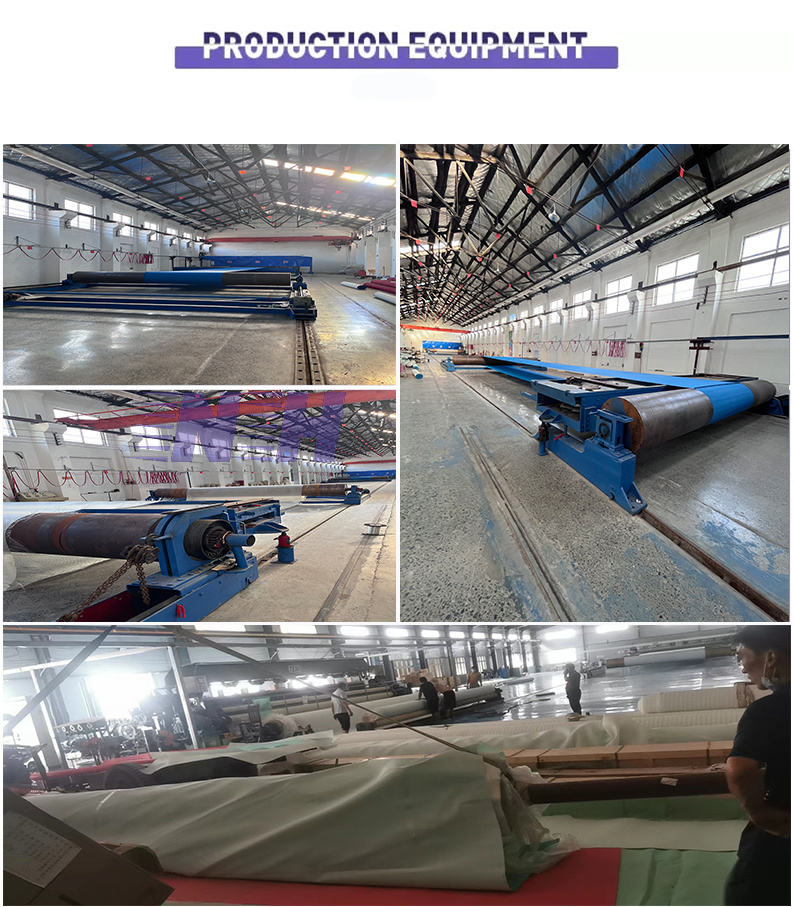

Production Process

Application

Packaging & Delivery

Comapny Introduction

NH Paper Machinery Industrial Group is a leading professional paper machine manufacturer in China, which specializes in making machine, paper making machine and all kinds of paper machine components manufacturing. Based on the development of local market ,we are growing to professional paper mill solution provider. NH Paper Machinery Industrial Group fully implement the guideline in business-"survival depends on quality and service ,market rely on price and brand."

Our main products are a full set of new and second hand paper making equipment with a maximum net with of 6000mm and a working speed of 700m/min.It mainly includes a packaging paper production line with an annual output of 200,000-200,000 tons, a cultural paper production line with an annual output of 1-10 million tons, a tissue paper production line with an annual output of 20,000 tons and various special paper production lines.

Look forward to hearing from you sooner and establishing a long friendly business relationship with you . We promise we will do our best to help you .Besides ,welcome you to visit our factory at anytime.

According to the process, divided into different workshop .With strict quality control system to ensure the finished product quality .

Part of production equipment for you reference .

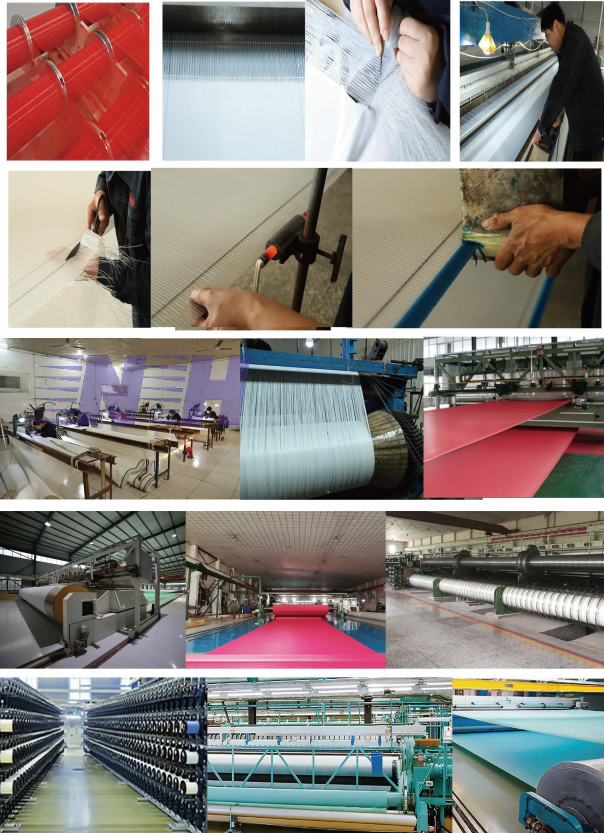

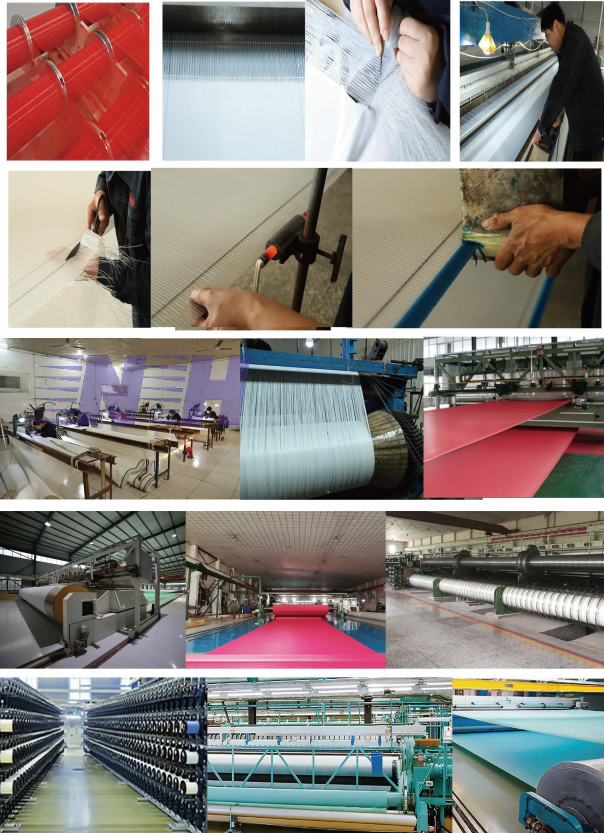

1. Special oil heat setting process,increase more than 40% service life.

2. Shuttless weaving process to extend the life of the monofilament.

3. Precise laser spot welding interface of stainless steel wire mesh to ensure the breathability and flatness of stainless steel wire mesh.

We have stable cooperation relationship with our clients.

The paper machine is an essential and remarkable piece of industrial equipment. It is designed with precision and expertise to transform raw materials into high-quality paper. Our paper machines are engineered to ensure efficient production processes, with advanced features and technologies that guarantee consistent paper quality.

Now, let’s turn our attention to the clothing aspect. Our clothing range is carefully curated to meet the diverse needs and preferences of customers. The fabrics used are selected for their comfort, durability, and style. Whether it’s for casual everyday wear or for more formal occasions, our clothing offers a perfect blend of fashion and functionality.

When it comes to paper machine clothing, we offer specialized protective gear. These are specifically designed to safeguard the paper machines and their operators. The machine clothing is made from tough and resilient materials that can withstand the demanding environment of a paper production facility. It provides essential protection against dust, dirt, and potential damage, ensuring the longevity and optimal performance of the machines.

In conclusion, our paper machine is a symbol of industrial innovation, while our clothing collection showcases style and quality. The paper machine clothing further emphasizes our commitment to safety and functionality. With our comprehensive range of products, we aim to meet the diverse requirements of both the paper industry and the fashion-conscious individuals.