Low concentration wood waste paper reed bamboo bagasse and straw pulp gravity disc thickener with large capacity and low power consumption

ZNP series gravity disc thickener is mainly used for the concentration of low-concentration slurry. This machine is different from the traditional vacuum disc filter. It does not need to be installed on the higher floors and is equipped with water leg pipes, which can replace the traditional gravity cylinder thickener.

Classification:

Product Description

|

Pulp species |

Chemical wood pulp |

Waste paperboard pulp |

Bamboo reed pulp

|

Offer waste paper |

Waste newspaper |

wheat straw pulp |

|

Capacity (T/dm2) |

2-2.2 |

1.8-2.2 |

1.4-1.6 |

1-1.3 |

0.9-1

|

0.9-1 |

|

Inlet pulp concentration |

0.8-1.2% |

|||||

|

Outlet pulp concentration |

3-4% |

|||||

|

Model/ Item |

ZNP50 |

ZNP75 |

ZNP100 |

ZNP120 |

ZNP150 |

ZNP180 |

ZNP210 |

ZNP240 |

|

Filter area m2 |

50 |

75 |

100 |

120 |

150 |

180 |

210 |

240 |

|

Diameter of disc/quantity |

2500/8 |

2500/ 12 |

2500/ 16 |

3500/8 |

3500/ 10 |

3500/ 12 |

3500/ 14 |

3500/ 16 |

|

Fan-shaped plate number |

8*8 |

12*8 |

16*8 |

8*10 |

10*10 |

12*10 |

14*10 |

16*10 |

|

Driving motor |

11 |

15 |

22 |

22 |

22 |

22 |

22 |

30 |

|

Size |

4450*3880*3350 |

5490* 3880* 3350 |

6530* 3880* 3350 |

4730* 5080* 4500 |

5330* 5080* 4500 |

5930* 5080* 4500 |

6530* 5080* 4500 |

7130* 5080* 4500 |

|

Washing mesh water pressure MPa |

0.5-0.7 |

|||||||

|

Rotate speed r/min |

1-4 |

|||||||

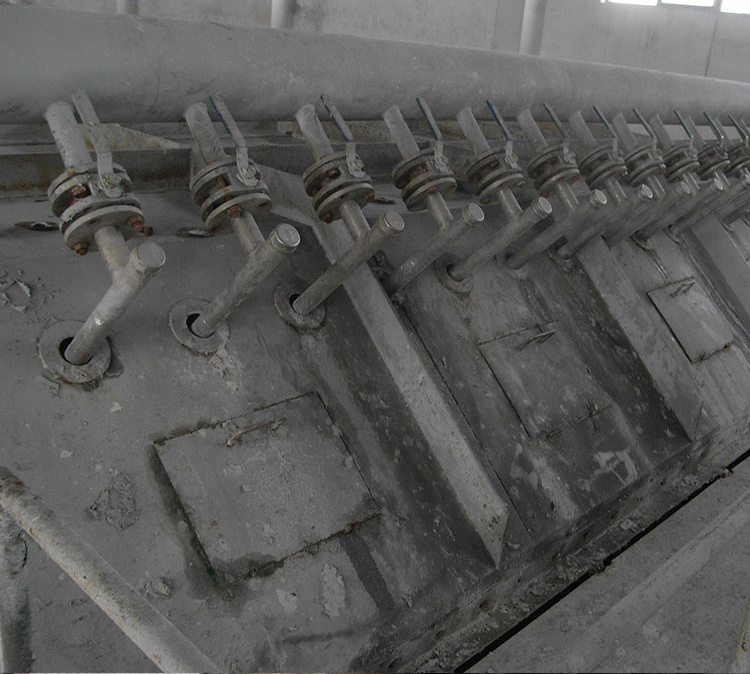

Main Structure

This machine is mainly composed of disc shaft, trough, hood, main transmission device, etc.

1) Fan-shaped plate: adopts a perforated plate structure, covered with a stainless steel filter screen, and the fan-shaped plate and the hollow main shaft are connected by bolts.

2) Hood: welded by steel plate

3) Tank body: The tank body supports the transmission device and all parts, and is welded by steel plates, including the feed box, the discharge box and the middle tank.

4) Both ends are sealed with rubber packing

5) The main drive form: the direct-connected suspension reducer is used for speed reduction, and the inverter speed is adjusted. The user can choose the best speed according to the production needs.

Screen washing device: 0.5-0.7Mpa high-pressure water sprayed from the nozzle on the water spray pipe to wash off the slurry adhering on the surface of the filter screen, and the filter screen is washed to obtain the regeneration capacity of the filter screen.

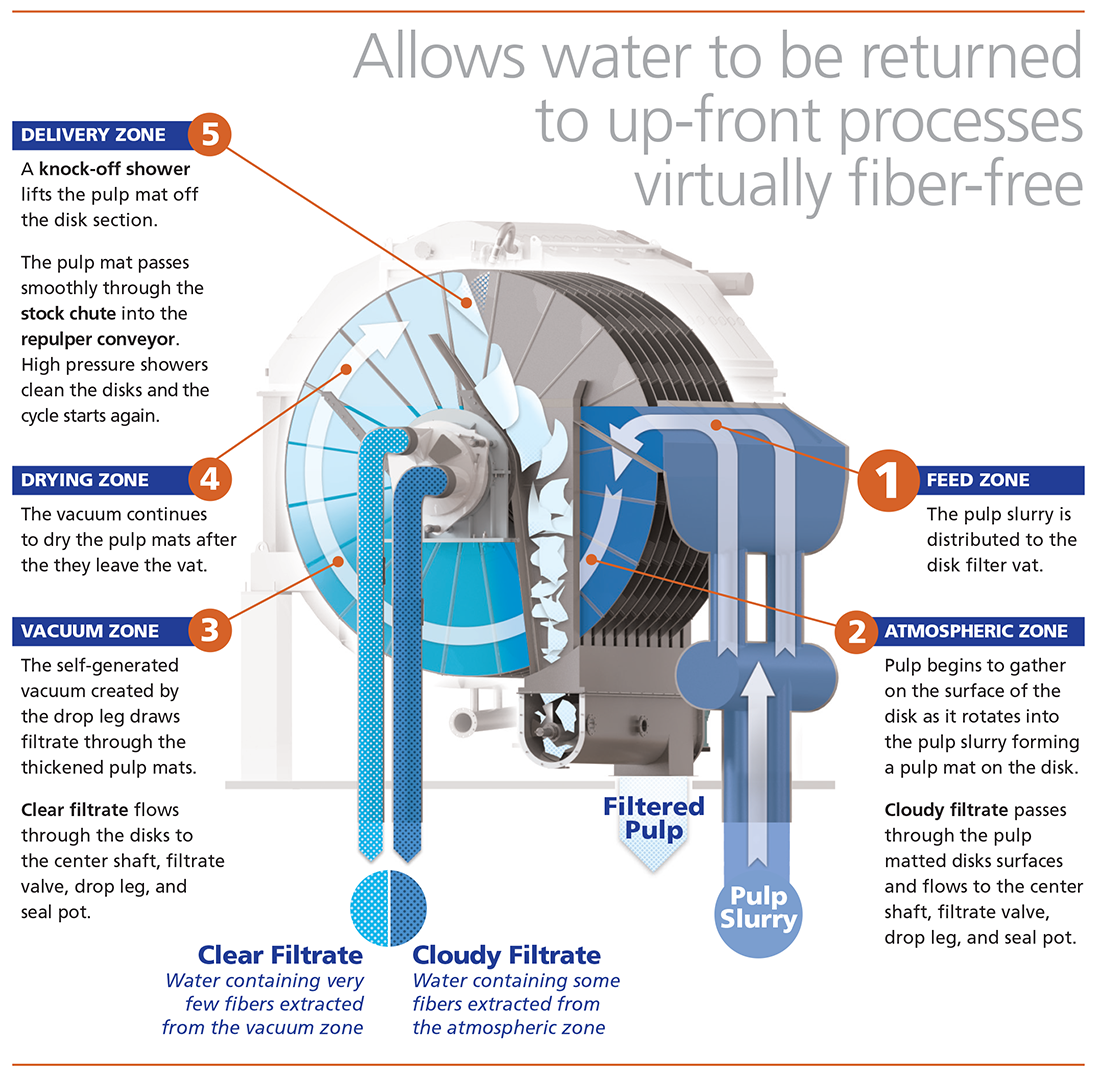

Work Principle

The central spindle of the filter is composed of several filter discs. Each disc is composed of 8-10 fan-shaped plates with the same size and equal area. The fan-shaped plates are fixed on the hollow shaft by bolts. The hollow shaft is connected with the fan-shaped plates. In the working process, with the rotation of the main shaft, when the fan-shaped plate is submerged below the liquid level, there is a liquid level difference between the inside and outside of the fan-shaped plate. Under the action of the liquid level difference, the water in the slurry passes through the covering The filter screen outside the fan-shaped plate enters the hollow shaft and flows out through the hollow shaft and the pipe. The slurry is intercepted by the filter screen to achieve slurry-water separation. When the slurry covering the filter screen turns out of the liquid surface on the fan-shaped plate, due to the liquid level The difference disappears and the adhesion is lost, and it is automatically peeled under the action of gravity. The peeled high-concentration slurry will overflow into the slurry outlet along with the operation of the disk to achieve the purpose of concentration.

Detail

Application

Service

Pre-Sales Service

1. Proposing the most suitable scheme and equipment for our clients.

2. Designing and fabricating targeted products according to the special requirements of clients.

3. Training periodically high qualified service technician.

After-Sales Service

1.Field installation, commissioning and training

2.Video technical support

3.Field maintenance and repair service

4.Online support

Packaging & Delivery

Company Introduction

NH Paper Machinery Industrial Group is a leading professional paper machine manufacturer in China, which specializes in making machine, paper making machine and all kinds of paper machine components manufacturing. Based on the development of local market. We are growing to professional paper mill solution provider. NH Paper Machinery Industrial Group fully implement the guideline in business-"survival depends on quality and service market rely on price and brand."

Our main products are a full set of new and second-hand paper making equipment with a maximum net with of 6000mm and a working speed of 700m/min. It mainly includes a packaging paper production line with an annual output of 200,000-200,000 tons, a cultural paper production line with an annual output of 1-10 million tons, a tissue paper production line with an annual output of 20,000 tons and various special paper production lines.

Look forward to hearing from you sooner and establishing a long friendly business relationship with you. We promise we will do our best to help you. Besides, welcome you to visit our factory at any time.

According to your requirement, there are different consistency slag removal equipment, as different capacity required, there are product customized for you.

We have stable cooperation relationship with our clients.

Key words:

Related Products

Welcome your product consultation

Qinyang NH Paper Machinery Industrial Group Co., Ltd.

WhatsApp/WeChat:Cathy Wang 0086-15721522521

WhatsApp/WeChat:Ailsa Zhao 0086-18300605679

ADD: Jianshe Road(South),Qinyang City Henan Province,China

Cathy Wang

Alisa Zhao

TikTok

Copyright©Qinyang City Nianhai Net Industry Co., Ltd.

SAF Coolest v1.3.1.1 设置面板 AIVSX-ZBBO-FQSEE-ZAS

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page