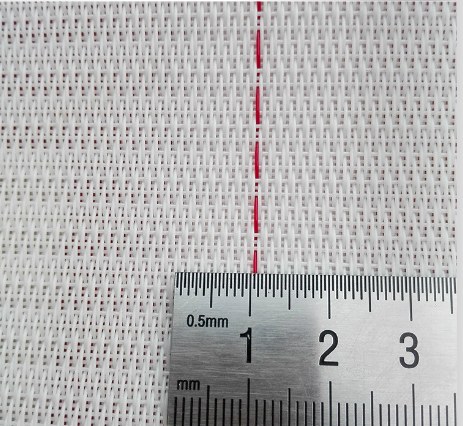

Long service stable working non-woven & melt-blown fabric drying conveying forming belt easy peeling with good air permeability

Desulfurization and denitration filter cloth for steel plant flue gas desulfurization belt for power plant from factory can be divided into gold mine filter cloth, iron mine factory filter cloth, sulfur draft phosphorus paste vacuum belt filter cloth, chemical fertilizer factory vacuum belt filter cloth, steel plant desulfurization and denitrification filter cloth, power plant desulfurization filter cloth, etc.

Classification:

Product Description