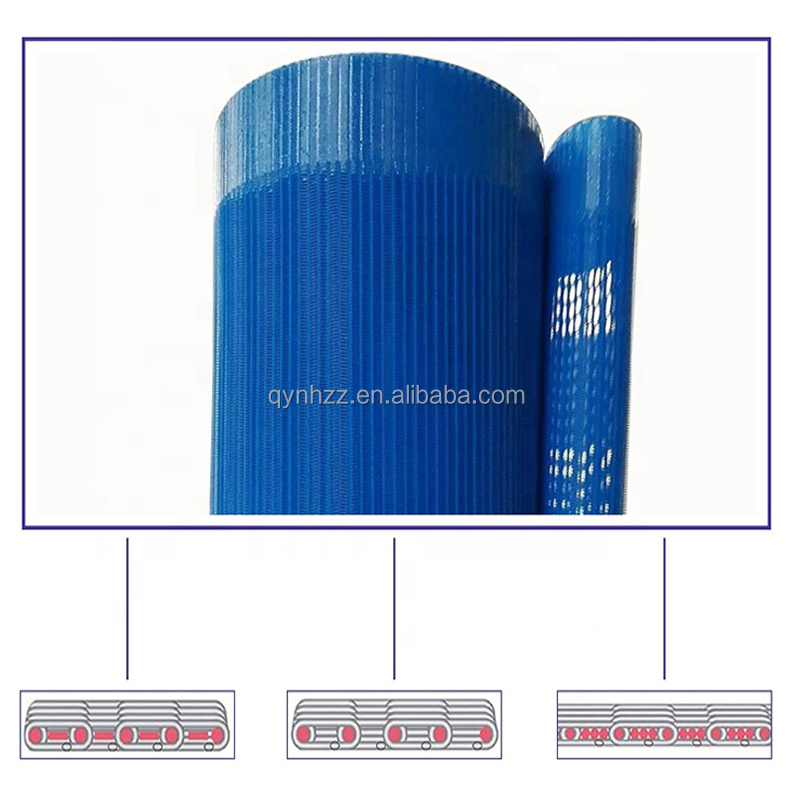

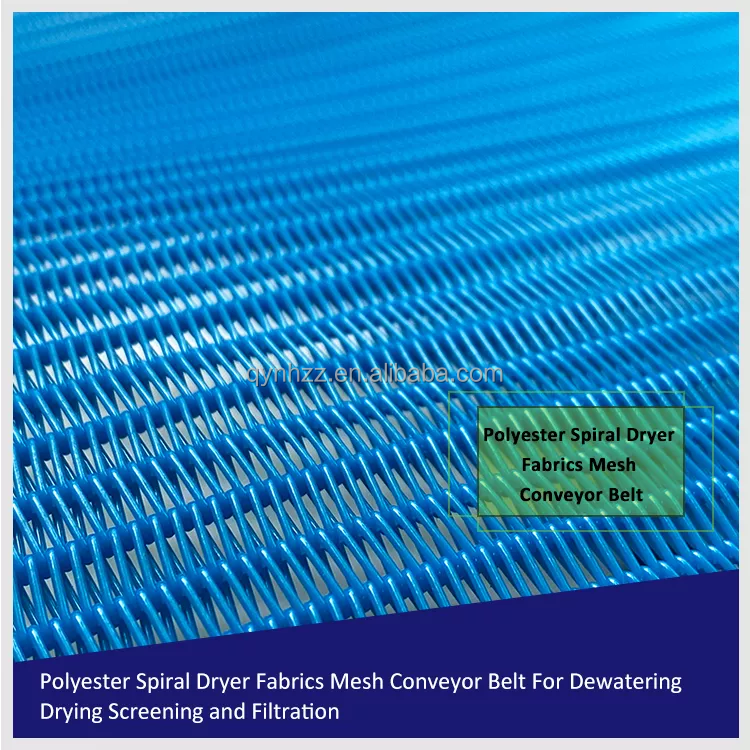

Polyester spiral dryer belt paper mill drying mesh belt for packaging cultural board paper and pulp board

Mainly used for paper drying in paper mills, textile printing and dyeing products, suitable for speeds below 600m/s. Suitable for bottom belt of horizontal belt vacuum washing machine (replace rubber belt).

Classification:

Product Description

|

Type |

Spiral loop width mm |

Filament diameter mm |

Tensile strength N/cm |

Weight Kg/m2 |

Thickness mm |

Air permeability m3/m3h |

Air permeability CFM 127/Pa |

||

|

Spiral ring monofilament mm |

Connection wire mm |

Filler material monofilament |

|||||||

|

Small loop 5080A2 |

5.2 |

0.5 |

0.8 |

0.6*3 |

1800 |

1.5 |

2.1 |

4480 |

280 |

|

Middle loop 6890A2 |

8 |

0.68 |

0.9 |

0.8*4 |

2000 |

2.0 |

2.45 |

6080 |

380 |

|

Middle loop 6890B1 |

7.15 |

0.68 |

0.9 |

0.9*3 |

2000 |

1.9 |

2.45 |

5760 |

360 |

|

Middle loop 6890B2 |

7.15 |

0.68 |

0.9 |

0.8*3 |

2000 |

1.85 |

2.45 |

19000 |

1188 |

|

Middle loop 6890B3 |

6.48 |

0.68 |

0.9 |

2.1*0.8 |

2000 |

1.8 |

2.45 |

14000 |

875 |

|

Middle loop 6890B4 |

8.3 |

0.68 |

0.9 |

2.4*0.88 |

2000 |

1.85 |

2.45 |

19000 |

1188 |

|

Middle loop 6890B5 |

10 |

0.68 |

0.9 |

Conductive carbon filament |

2000 |

1.6 |

2.45 |

20000 |

1250 |

|

Big loop 9090A2 |

8 |

0.9 |

0.9 |

0.9*3 |

2300 |

2.3 |

3.03 |

7500 |

468 |

|

Big loop 90110A2 |

10 |

0.9 |

1.1 |

1*4 |

2000 |

2.4 |

3.15 |

6240 |

390 |

|

PA90110A1 |

10 |

0.9 |

1.1 |

1.2*3 |

2000 |

2.25 |

3.15 |

6240 |

390 |

|

Big loop 10090A2 |

8 |

1 |

0.9 |

1*3 |

2000 |

2.5 |

3.6 |

5000 |

315 |

|

Big loop 120130A2 |

1.2 |

1.2 |

1.3 |

1.2*3 |

2600 |

2.85 |

4.3 |

7500 |

468 |

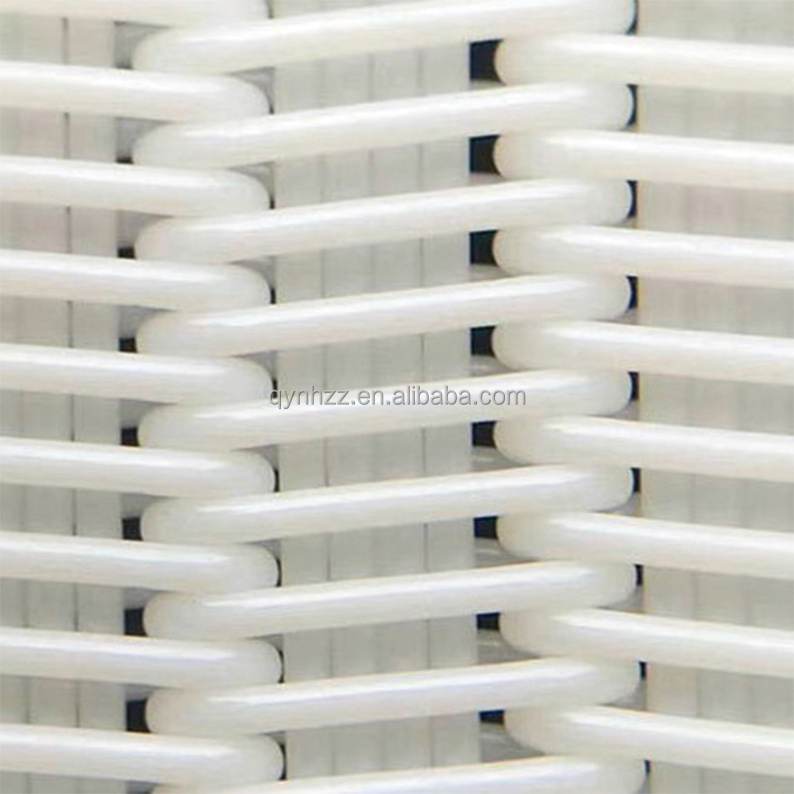

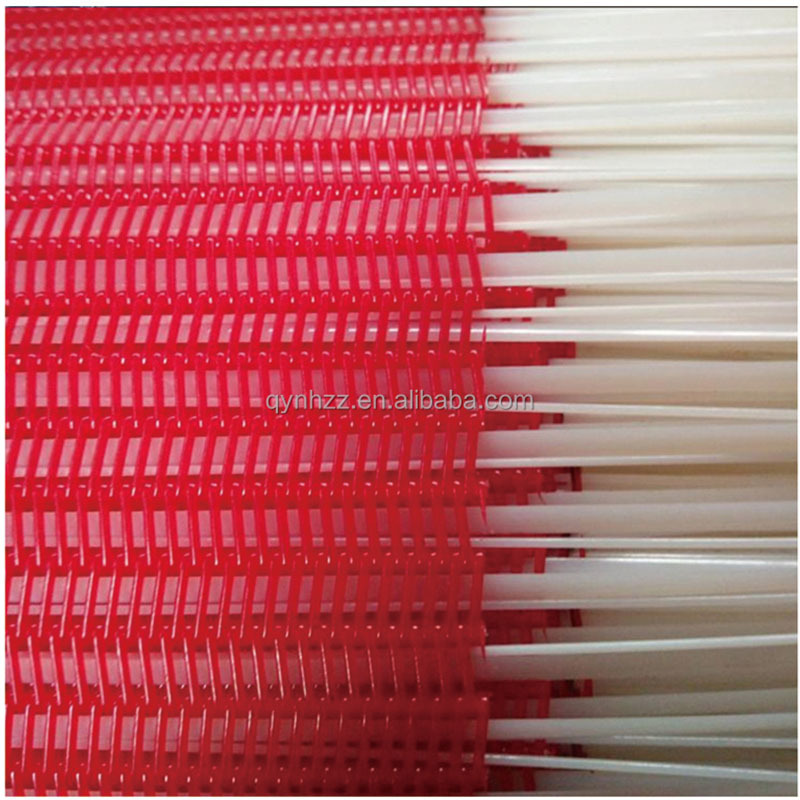

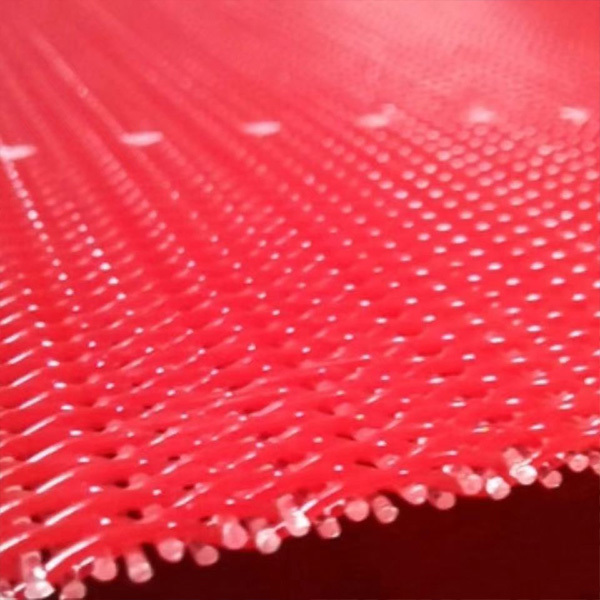

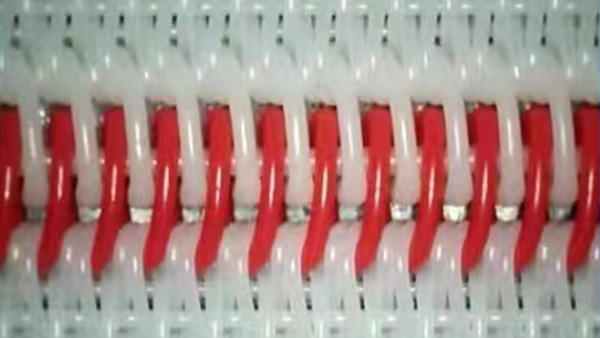

Detail

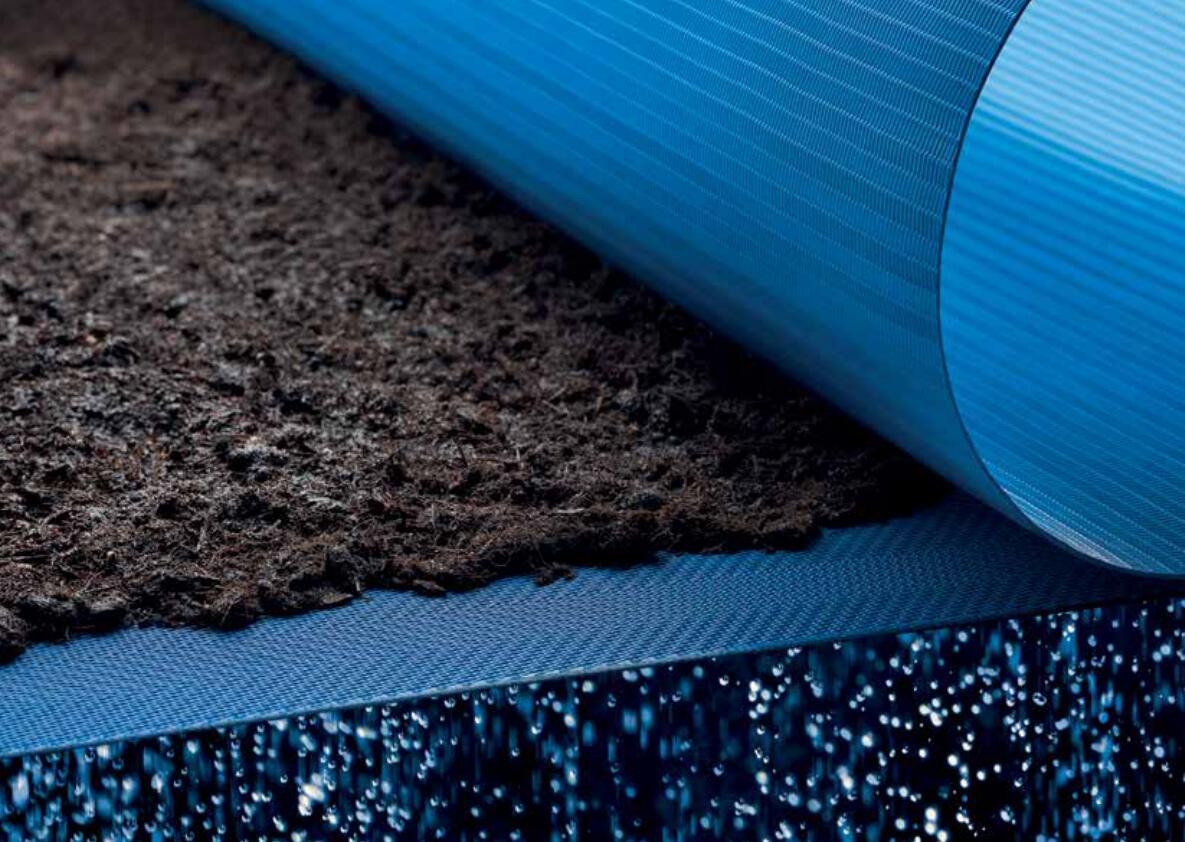

Application

The polyester spiral dryer fabric series is suitable for drying packaging paper, cultural paper, board paper and pulp board with large basis weight. It is widely used in papermaking, coal mine, food, medicine, printing and dyeing and rubber products industries. It can also be used as a conveyor belt and a mesh belt for compound machines.

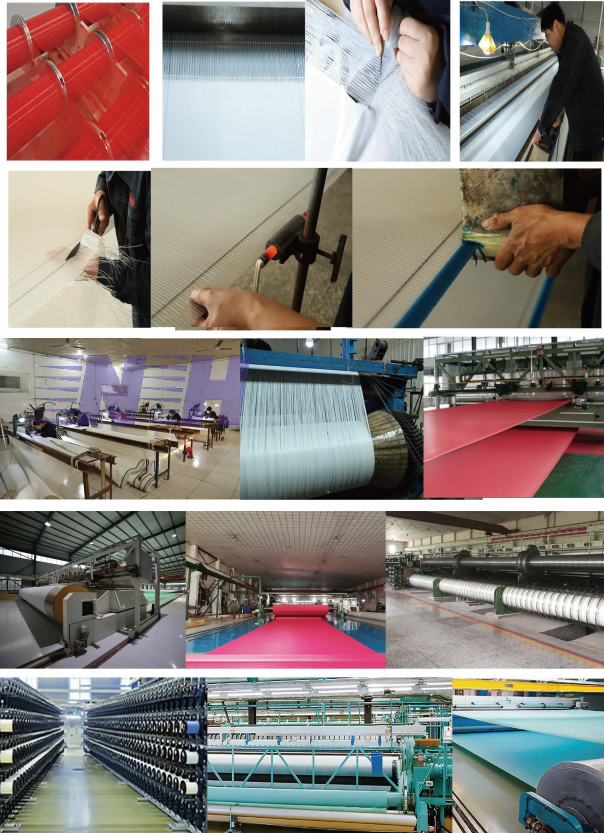

Production Process

Packaging & Delivery

Company Introduction

NH Paper Machinery Industrial Group is a leading professional paper machine manufacturer in China, which specializes in making machine, paper making machine and all kinds of paper machine components manufacturing. Based on the development of local market ,we are growing to professional paper mill solution provider. NH Paper Machinery Industrial Group fully implement the guideline in business-"survival depends on quality and service ,market rely on price and brand."

Our main products are a full set of new and second hand paper making equipment with a maximum net with of 6000 mm and a working speed of 700 m/min.It mainly includes a packaging paper production line with an annual output of 200,000-200,000 tons, a cultural paper production line with an annual output of 1-10 million tons, a tissue paper production line with an annual output of 20,000 tons and various special paper production lines.

Look forward to hearing from you sooner and establishing a long friendly business relationship with you . We promise we will do our best to help you .Besides ,welcome you to visit our factory at anytime.

According to the process, divided into different workshop .With strict quality control system to ensure the finished product quality .

Part of production equipment for you reference .

1. Special oil heat setting process,increase more than 40% service life.

2. Shuttless weaving process to extend the life of the monofilament.

3. Precise laser spot welding interface of stainless steel wire mesh to ensure the breathability and flatness of stainless steel wire mesh.

We have stable cooperation relationship with our clients.

Key words:

Related Products

Welcome your product consultation

Qinyang NH Paper Machinery Industrial Group Co., Ltd.

WhatsApp/WeChat:Cathy Wang 0086-15721522521

WhatsApp/WeChat:Ailsa Zhao 0086-18300605679

ADD: Jianshe Road(South),Qinyang City Henan Province,China

Cathy Wang

Alisa Zhao

TikTok

Copyright©Qinyang City Nianhai Net Industry Co., Ltd.

SAF Coolest v1.3.1.1 设置面板 AIVSX-ZBBO-FQSEE-ZAS

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page