Dryer Cylinder

Parameter

Features

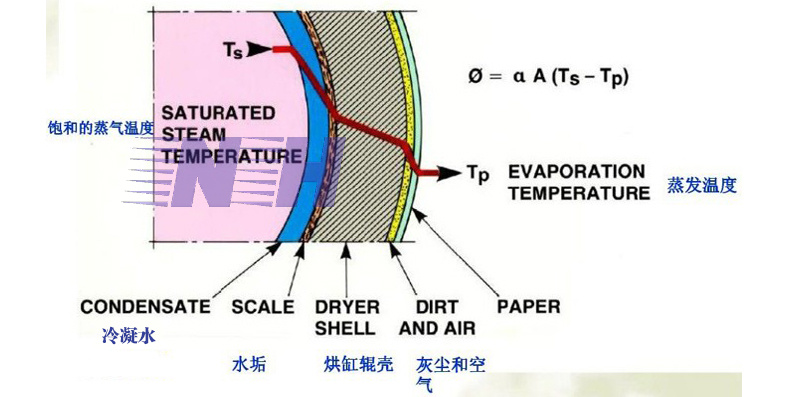

1) Excellent welding process applied for steel plates eliminating possible leakages

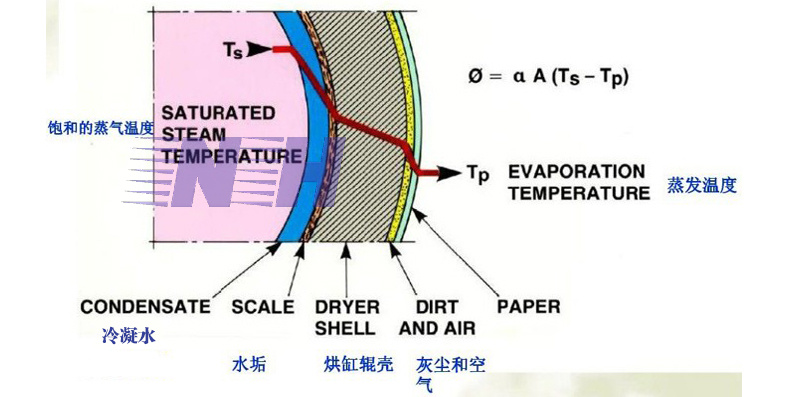

2) Increase cylinder drying capacity

3) Improve drying / moisture cross profile

4) Increase the area and the rate of water filtration, increase production

5) Improve the quality of paper, including the degree of uniformity, weight, aspect ratio

6) Reduce the copper net, cloth etc. consumption and maintenance cos

7) To strengthen the integrity of the equipment and anti-corrosion performance, durable

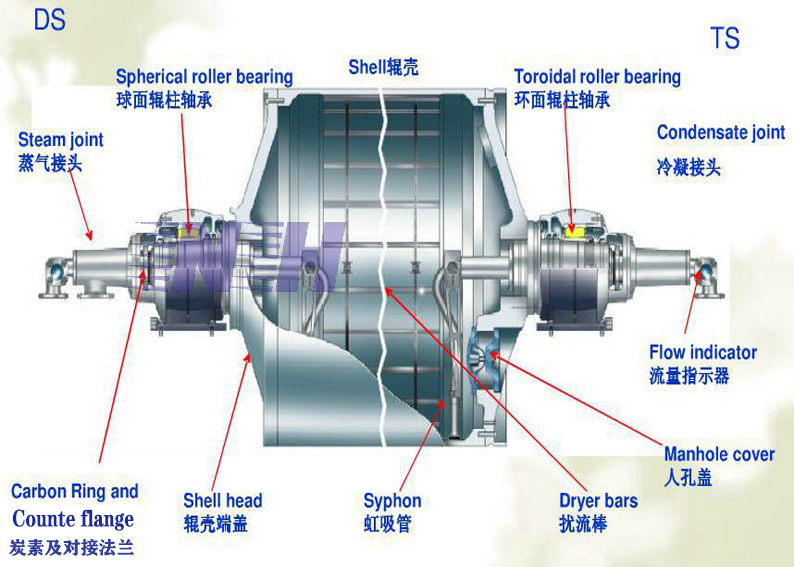

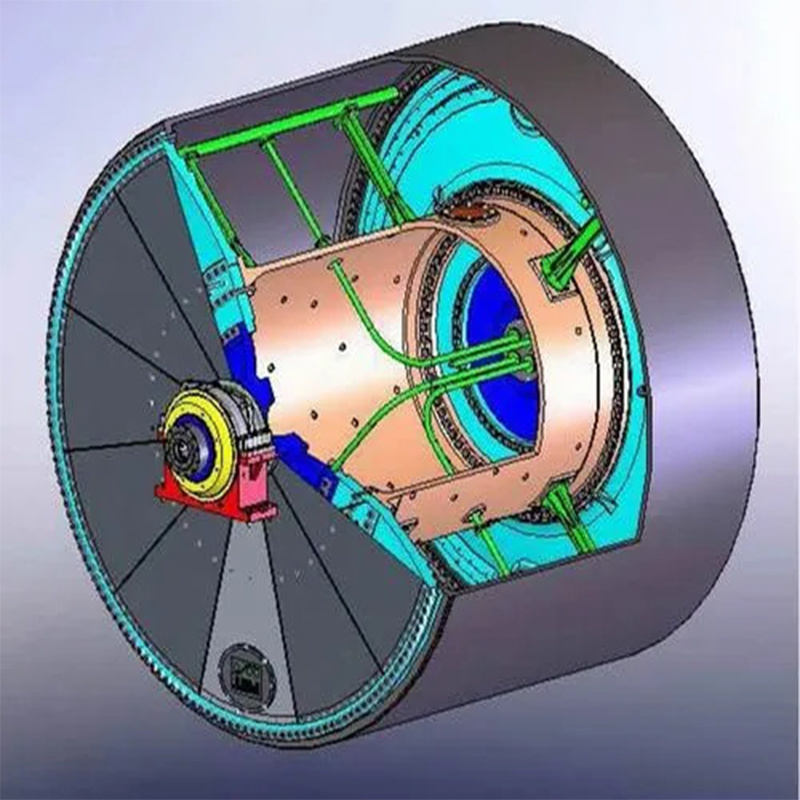

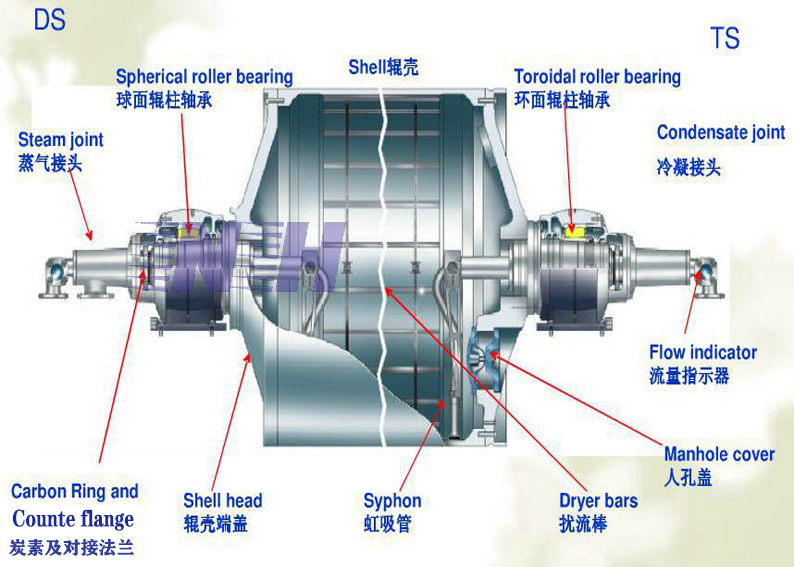

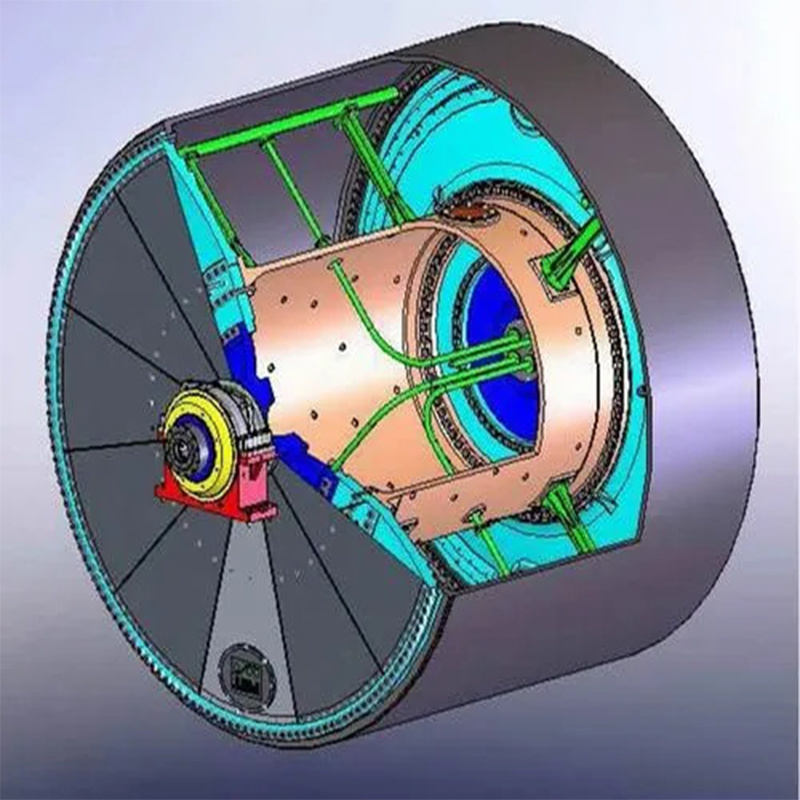

Structure

Product Detail

Application

Service

Pre-Sales Service

1. Proposing the most suitable scheme and equipment for our clients.

2. Designing and fabricating targeted products according to the special requirements of clients.

3. Training periodically high qualified service technician.

After-Sales Service

1.Field installation, commissioning and training

2.Video technical support

3.Field maintenance and repair service

4.Online support

Company file

NH Paper Machinery Industrial Group is a leading professional paper machine manufacturer in China, which specializes in making machine, paper making machine and all kinds of paper machine components manufacturing. Based on the development of local market ,we are growing to professional paper mill solution provider. NH Paper Machinery Industrial Group fully implement the guideline in business-"survival depends on quality and service ,market rely on price and brand."

Our main products are a full set of new and second hand paper making equipment with a maximum net with of 6000mm and a working speed of 700m/min.It mainly includes a packaging paper production line with an annual output of 200,000-200,000 tons, a cultural paper production line with an annual output of 1-10 million tons, a tissue paper production line with an annual output of 20,000 tons and various special paper production lines.

Look forward to hearing from you sooner and establishing a long friendly business relationship with you . We promise we will do our best to help you .Besides ,welcome you to visit our factory at anytime.

According to your requirement, there are different consistency slag removal equipment, as different capacity required, there are product customized for you.

We have stable cooperation relationship with our clients.

The paper making machine is an incredible piece of equipment that plays a vital role in the paper industry.

This machine is a complex and highly engineered marvel. It is designed to take raw materials, such as wood pulp or recycled fibers, and transform them into high-quality paper. The process involves a series of precise steps and operations.

The paper making machine begins by evenly distributing the pulp onto a moving screen or belt. From there, it goes through various stages of pressing and drying to remove moisture and give the paper its desired thickness and texture. Sophisticated control systems ensure that every aspect of the process is precisely regulated to achieve consistent results.

One of the remarkable aspects of the paper making machine is its ability to produce paper in a wide range of types and qualities. It can create paper that is suitable for printing, writing, packaging, and other applications. The machine can be adjusted to meet specific requirements, such as paper weight, smoothness, and opacity.

Furthermore, modern paper making machines are designed with efficiency and sustainability in mind. They are engineered to minimize waste and energy consumption while maximizing productivity. Many models incorporate advanced technologies to recycle water and reduce the environmental impact.

In addition to its technical capabilities, the paper making machine also offers ease of operation and maintenance. Well-designed interfaces and accessible components make it convenient for operators to manage and troubleshoot.

In conclusion, the paper making machine is a fundamental tool in the paper manufacturing process. It combines advanced technology, precision engineering, and a commitment to quality and sustainability. It is responsible for bringing us the essential paper products that we use in our daily lives and various industries. Whether it’s for books, newspapers, or packaging materials, the paper making machine is at the heart of it all.