Toilet Paper Rewinding Machine

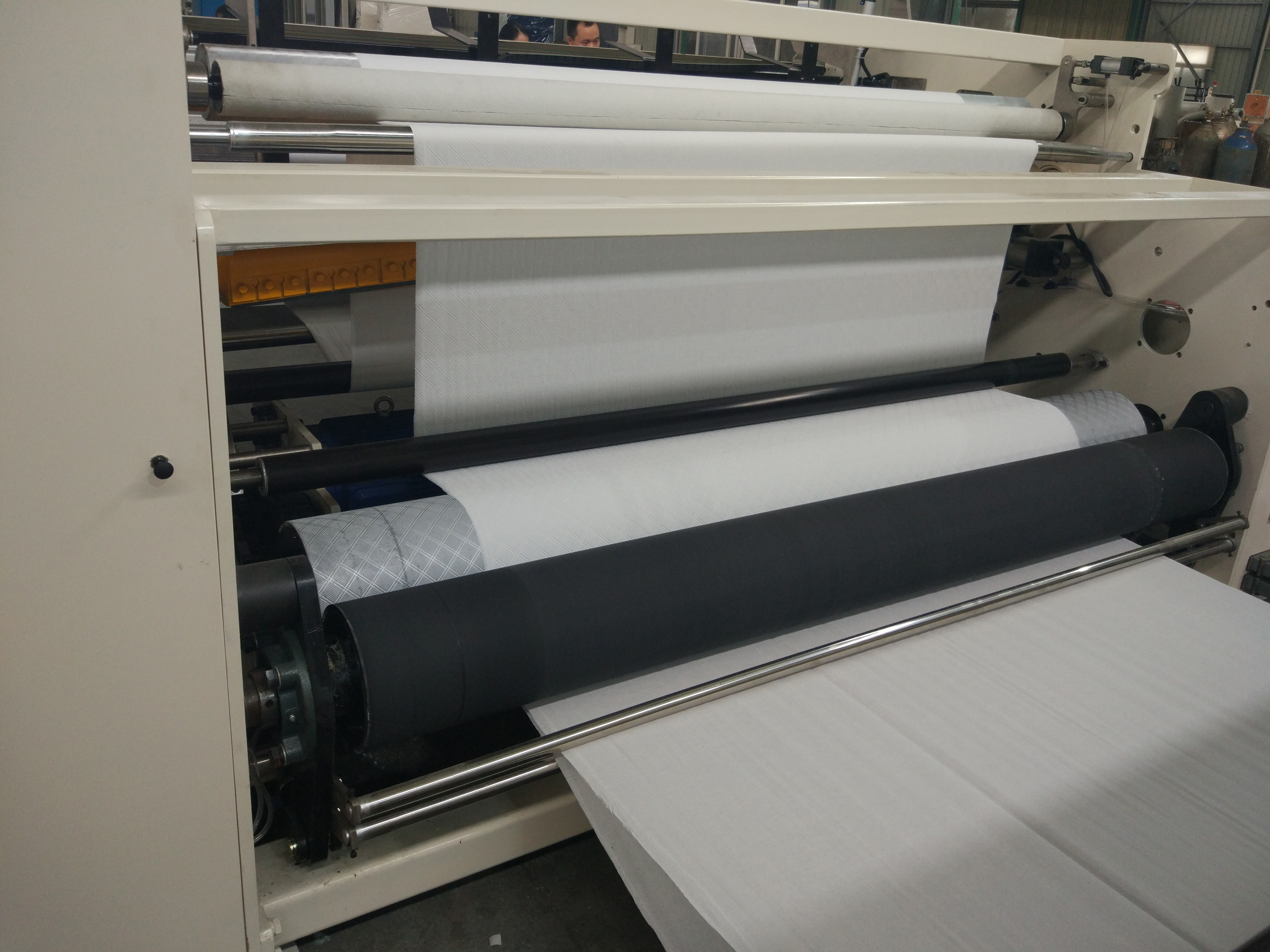

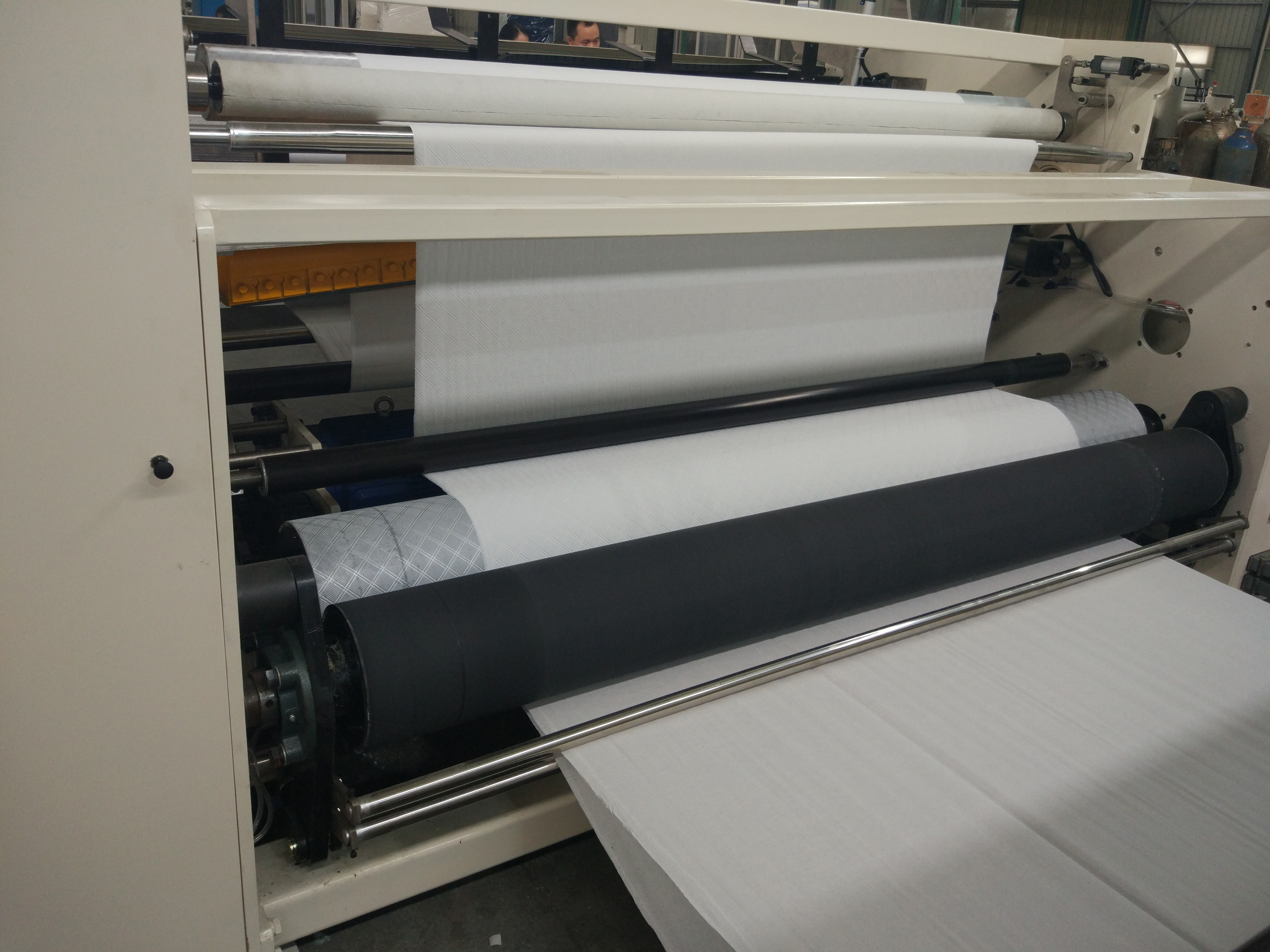

This machine adopts international new PLC computer programming technology (system can be upgraded), frequency control, automatic electronic brake. The touch-type human-machine interface operating system uses a coreless rewind forming system. application the PLC program wind column forming technology achieves the characteristics of faster rewinding and more beautiful molding.

Parameter

Feature

1. Using PLC computer to program the finished paper in the rewinding process to achieve the tightness and looseness of the different tightness to solve the looseness of the finished product due to long-term storage.

2. Full-automatic rewinding machine can choose double-sided embossing, gluing compound, which can make paper more soft than single-sided embossing, the effect of double-sided finished products is consistent, and each layer of paper does not spread when used, especially suitable for processing. Roll up kitchen paper towels and reduce weight by 15% or more when finished in the same size.

3. The machine is equipped with processing unintentional, solid, paper tube toilet paper, which can instantly switch between products, and can also be selected according to user needs.

4. Automatic trimming, glue spraying, sealing, and shafting are completed synchronously, so that there is no paper loss when the roll paper is cut into the band saw and packaged, which greatly improves the production efficiency and the grade of the finished product. Easy to enable.

5. Pneumatic belt feeding, double reel and each axis of the original paper have independent tension adjustment mechanism.

Full Automatic Production Line

Semi-automatic Production Line

Workshop

Service

Pre-Sales Service

1. Proposing the most suitable scheme and equipment for our clients.

2. Designing and fabricating targeted products according to the special requirements of clients.

3. Training periodically high qualified service technician.

After-Sales Service

1.Field installation, commissioning and training

2.Video technical support

3.Field maintenance and repair service

4.Online support

Pakaging and Delivery

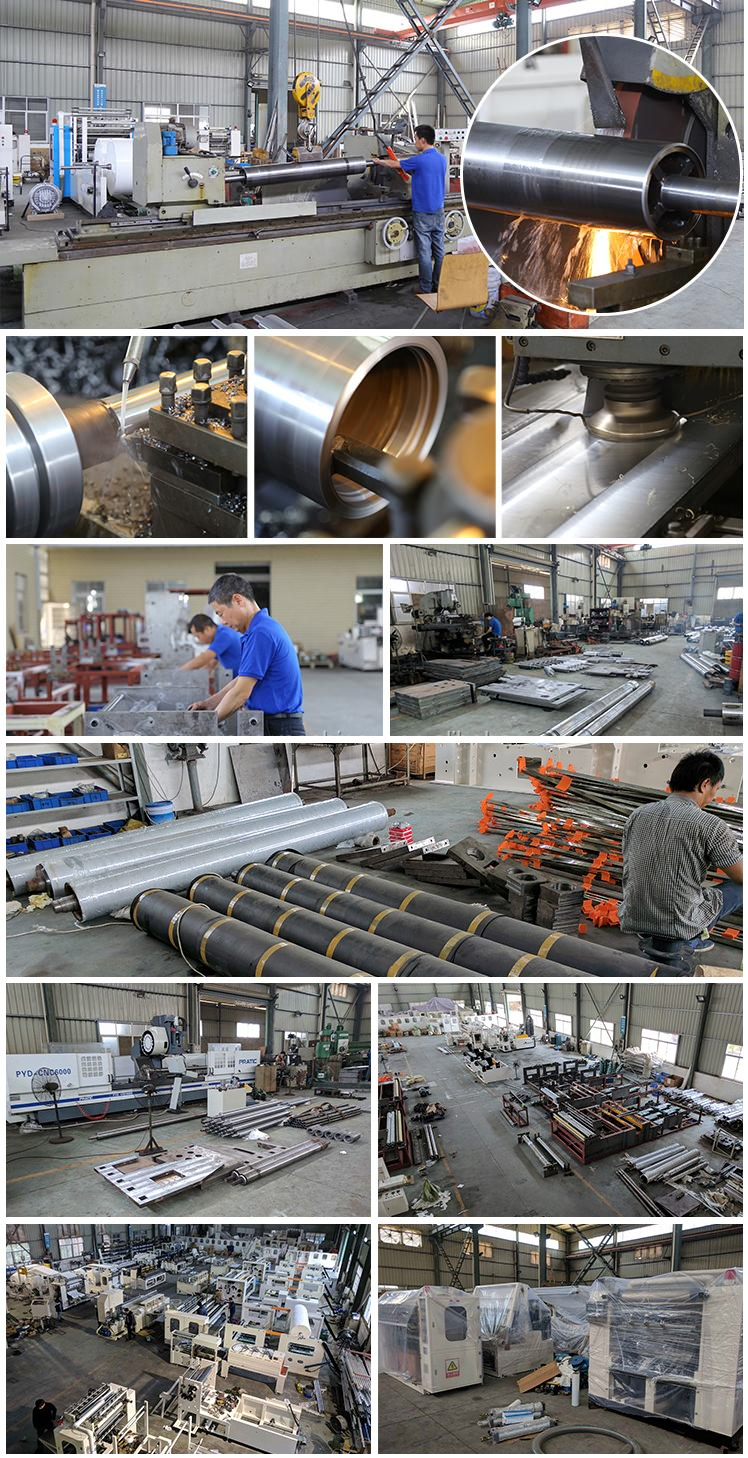

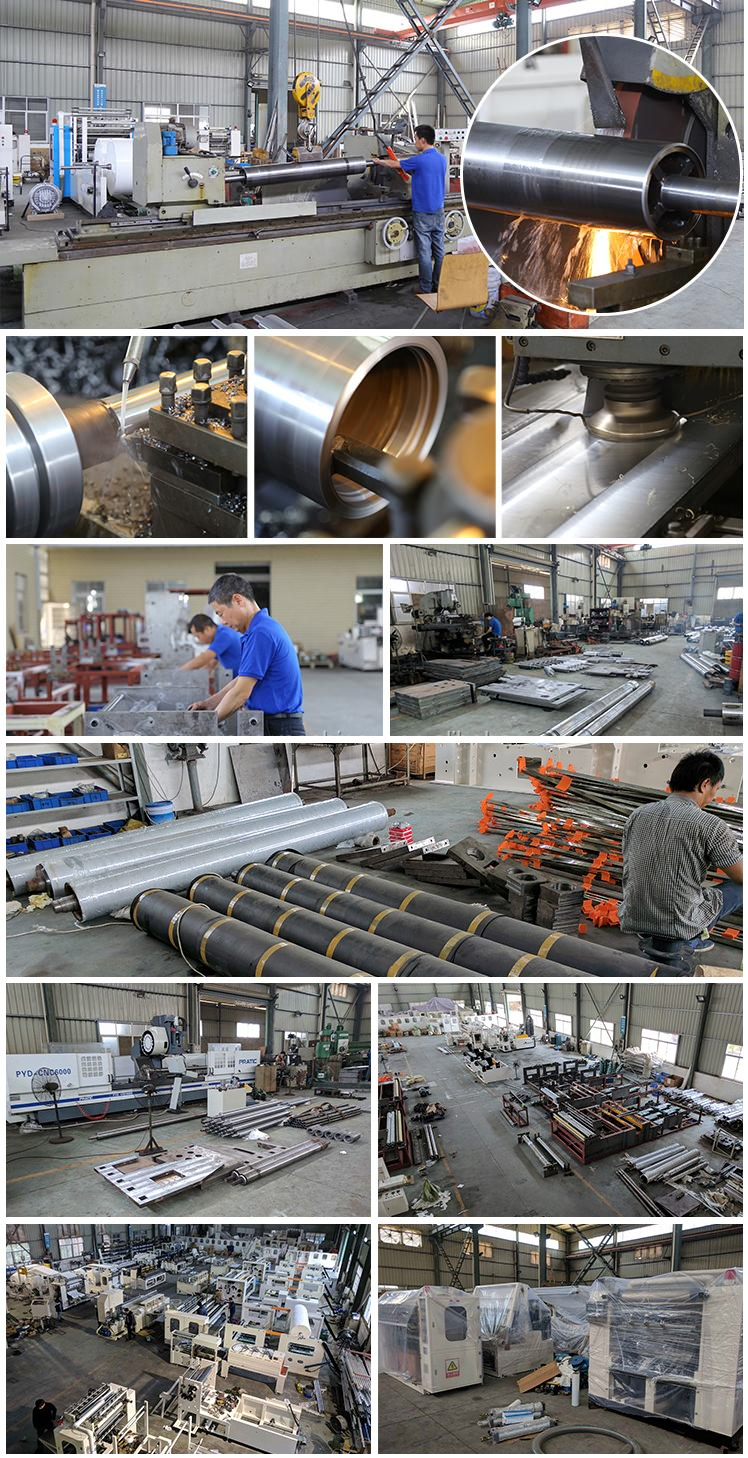

Company Introduction

NH Paper Machinery Industrial Group is a leading professional paper machine manufacturer in China, which specializes in making machine, paper making machine and all kinds of paper machine components manufacturing. Based on the development of local market ,we are growing to professional paper mill solution provider. NH Paper Machinery Industrial Group fully implement the guideline in business-"survival depends on quality and service ,market rely on price and brand."

Our main products are a full set of new and second hand paper making equipment with a maximum net with of 6000mm and a working speed of 700m/min.It mainly includes a packaging paper production line with an annual output of 200,000-200,000 tons, a cultural paper production line with an annual output of 1-10 million tons, a tissue paper production line with an annual output of 20,000 tons and various special paper production lines.

Look forward to hearing from you sooner and establishing a long friendly business relationship with you . We promise we will do our best to help you .Besides ,welcome you to visit our factory at anytime.

According to the process, divided into different workshop. With strict quality control system to ensure the finished product quality.

We have stable cooperation relationship with our clients.