Toilet tissue paper make mill ceramic embossing roller

Roller is used in paper, textile, printing and dyeing, iron and steel industry, from the drive guide, material selection, high-quality, seamless, roller surface coated rubber, composite, Copper or Chrome.

Classification:

Product Description

|

1, a wide range of hardness: 20-100 degrees |

|

2, high temperature resistance, up to 300 degrees |

|

3, oil resistance, wear resistance, solvent resistance, acid and alkali resistance, aging resistance |

|

4, strong production capacity, a variety of mature formulations, but also for the customer design and build. |

|

5, a large range of processing, ultra-long roller manufacturing experts.(diameter 10MM-670MM, length: 50MM-8200MM) |

Application

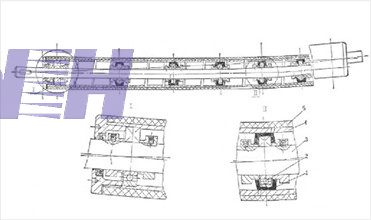

A long net paper machine generally has 70 to 80 rubber rollers. According to the structure, it can be divided into light roller (flat roller, no pattern on the surface), groove roller (groove on the surface of the coating layer), thread roller (thread groove on the surface of the coating layer), vacuum roller, movable arc roller (Hollow bending rolls) and medium and high rolls. They are used for different parts of the paper machine to squeeze water, press, calender and so on. It is generally made of various SRs (such as PU).

Glue roll of paper mill

The adhesive layer has good elasticity, compression resistance, flex resistance and thermal conductivity. The maximum tolerance of the hardness should be within the allowable range, otherwise the unevenness of the pulp will be uneven and the quality of the paper will be affected. Generally, the Shore hardness is 40°~100°, and the tolerance is ±2°~±4°.

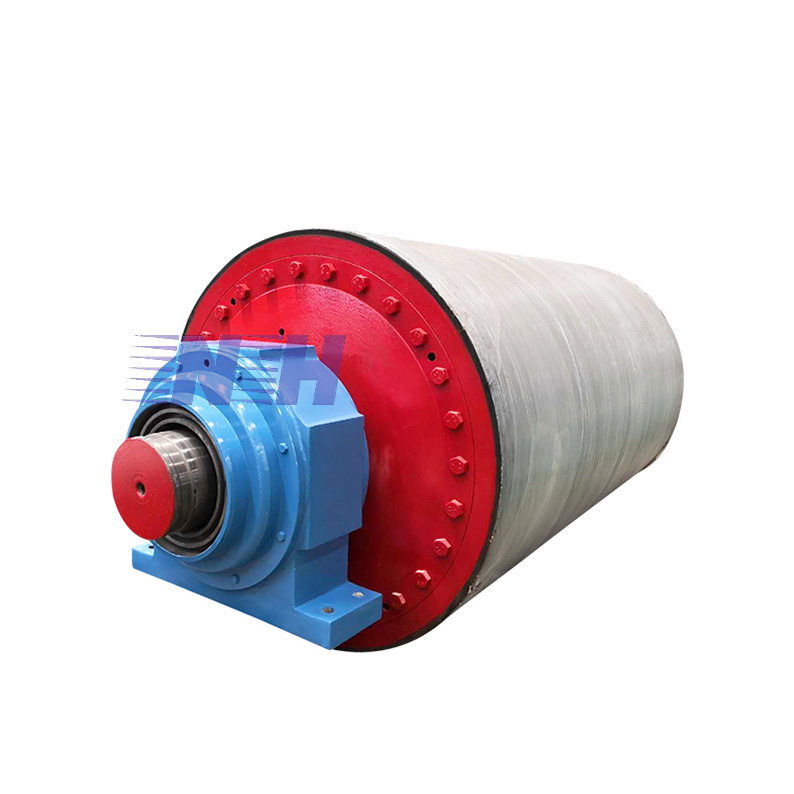

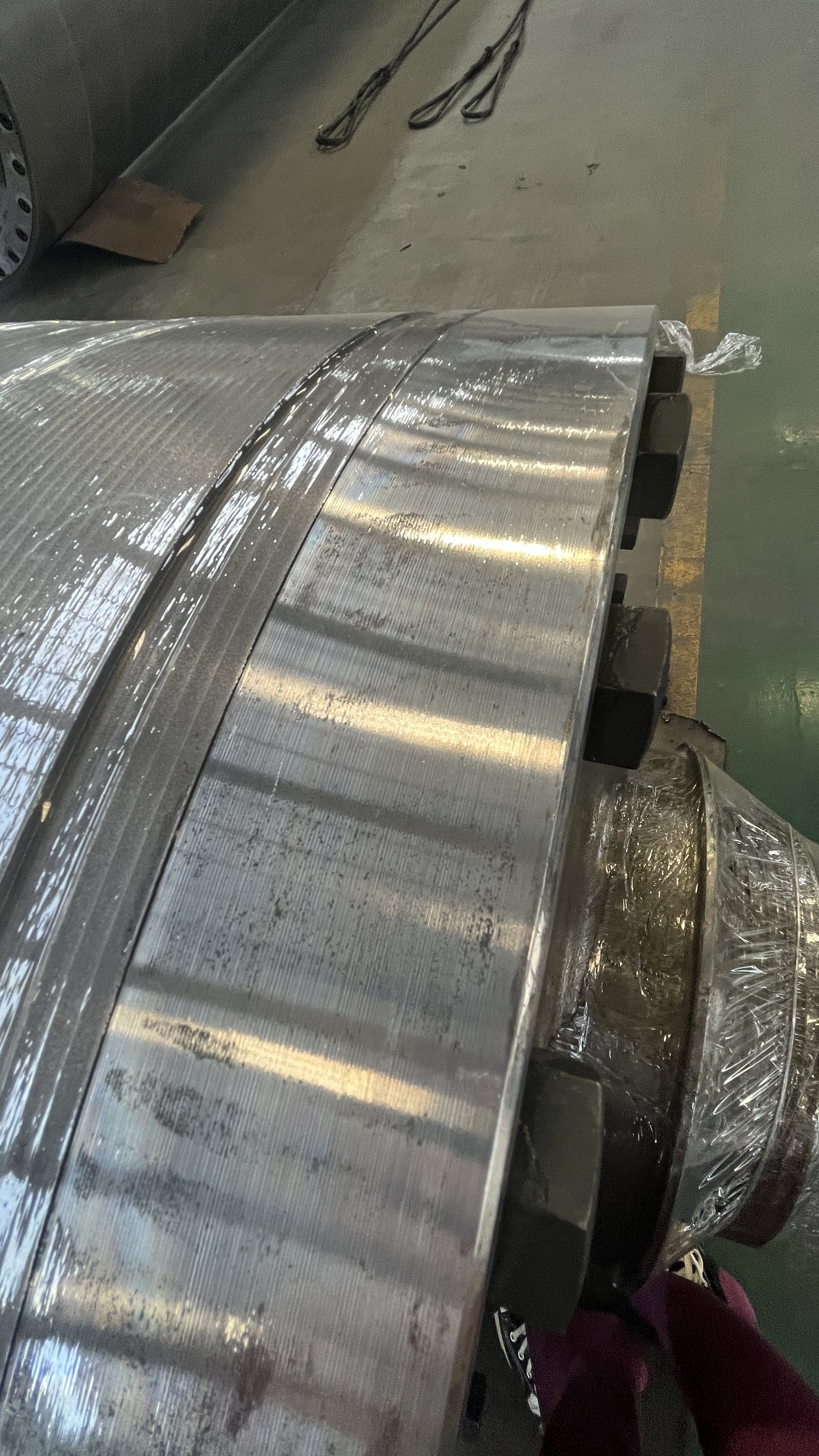

Stone roll of paper mill

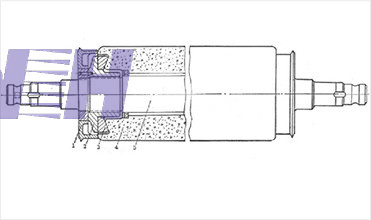

The press section consists of two rolls of hard and soft rolls, such as stone rolls and rubber rolls, whichare combined to form a set of presses. The press section consists of a press pack of the same or different form, which also customarily includes a vacuum pipetting device. When pressing, the paper is supported by a cloth of appropriate specifications, which can evenly pressurize the pressure and take away some of the water squeezed out by the press, and can increase the pressure of the pressurization and improve the dewatering ability of the press.

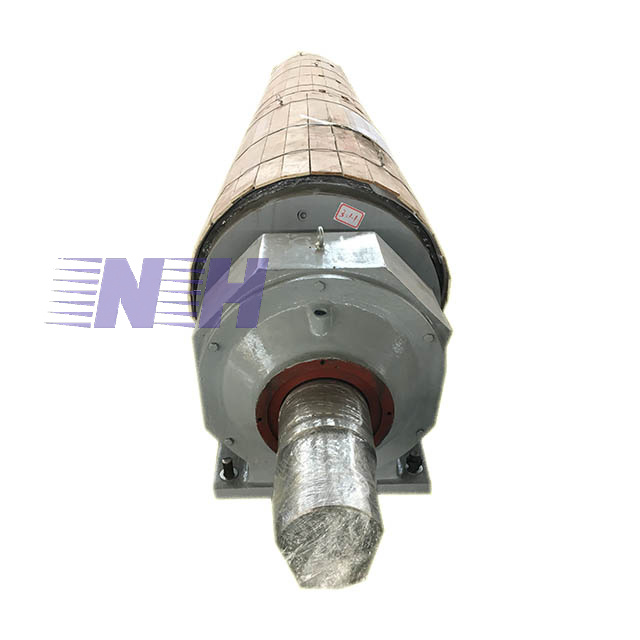

Vacuum press roll of paper mill

The surface is drilled dual helix aligned holes, holes diameter 4mm, opening rate 12.2%. Roll body is made by SUS304. Vacuum box body, water pipes and connecting parts are stainless steel. The whole chambers can be taken out for maintenance. The max. suction width is 3850mm, min. suction width is 3430mm. Suction width can be adjusted at operation side. There are air bellow and sealing trip in the roll, air bellow pressure is 0.025-0.07MPa, with shower inside. Sealing strip materials is graphite rubber.

Curved roll of paper mill

Applied to stretch paper, wire, blanket felt. Roller inside and outside surface will be processed. We will do dynamic balance to improve the stability of the roller.After shaft head installed, we will do dynamic balance again.The dynamic balance will be G1

Rubber roll of paper mill

Special coated material with good Rubber toughness and uniform; Tapping area up to 50% ,specially designed buffer layer helps disperse stress and mechanical shock resistance effectively during operating; Excellent dehydration ,low nip pressure which prevents dandy marks and crushing of paper sheet ;High wear resistance ,chemical resistance. The rubber roller has moderate hardness and elasticity, high oil resistance, washing solvent resistance, wear resistance and shape stability. Soft rolls are generally made of SBR, CR and PU. The surface of the hard stick was originally made of copper and later replaced with polyester resin.

Product Detail

Working Site

Service

Pre-Sales Service

1. Proposing the most suitable scheme and equipment for our clients.

2. Designing and fabricating targeted products according to the special requirements of clients.

3. Training periodically high qualified service technician.

After-Sales Service

1.Field installation, commissioning and training

2.Video technical support

3.Field maintenance and repair service

4.Online support

Packaging & Delivery

Company Introduction

NH Paper Machinery Industrial Group is a leading professional paper machine manufacturer in China, which specializes in making machine, paper making machine and all kinds of paper machine components manufacturing. Based on the development of local market ,we are growing to professional paper mill solution provider. NH Paper Machinery Industrial Group fully implement the guideline in business-"survival depends on quality and service ,market rely on price and brand."

Our main products are a full set of new and second hand paper making equipment with a maximum net with of 6000mm and a working speed of 700m/min.It mainly includes a packaging paper production line with an annual output of 200,000-200,000 tons, a cultural paper production line with an annual output of 1-10 million tons, a tissue paper production line with an annual output of 20,000 tons and various special paper production lines.

Look forward to hearing from you sooner and establishing a long friendly business relationship with you . We promise we will do our best to help you .Besides ,welcome you to visit our factory at anytime.

We have stable cooperation relationship with our clients.

Key words:

Related Products

Welcome your product consultation

Qinyang NH Paper Machinery Industrial Group Co., Ltd.

WhatsApp/WeChat:Cathy Wang 0086-15721522521

WhatsApp/WeChat:Ailsa Zhao 0086-18300605679

ADD: Jianshe Road(South),Qinyang City Henan Province,China

Cathy Wang

Alisa Zhao

TikTok

Copyright©Qinyang City Nianhai Net Industry Co., Ltd.

SAF Coolest v1.3.1.1 设置面板 AIVSX-ZBBO-FQSEE-ZAS

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page