High temperature durable 3 Layer Bottom Paper Making Felt for cellophane in paper to dry in paper mill

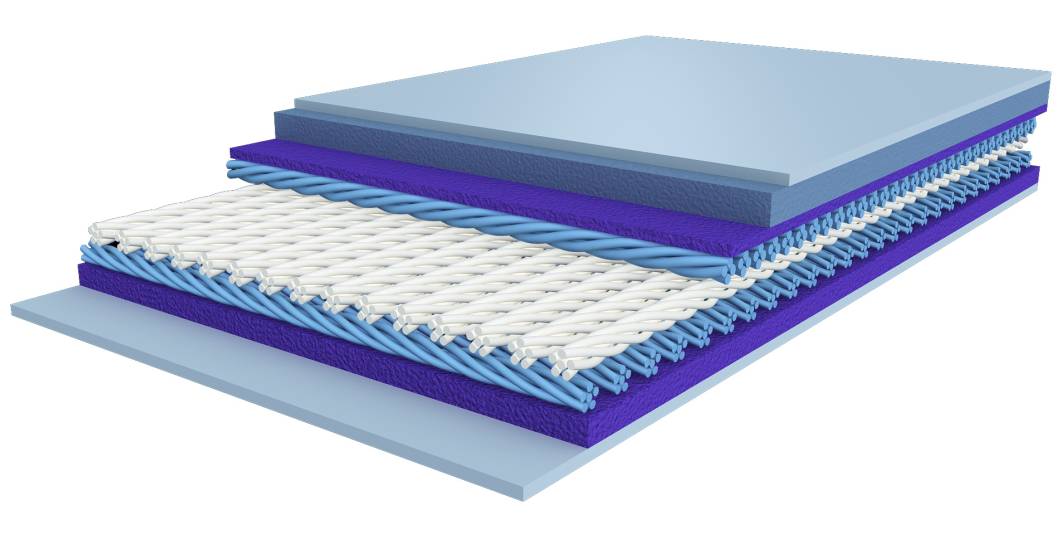

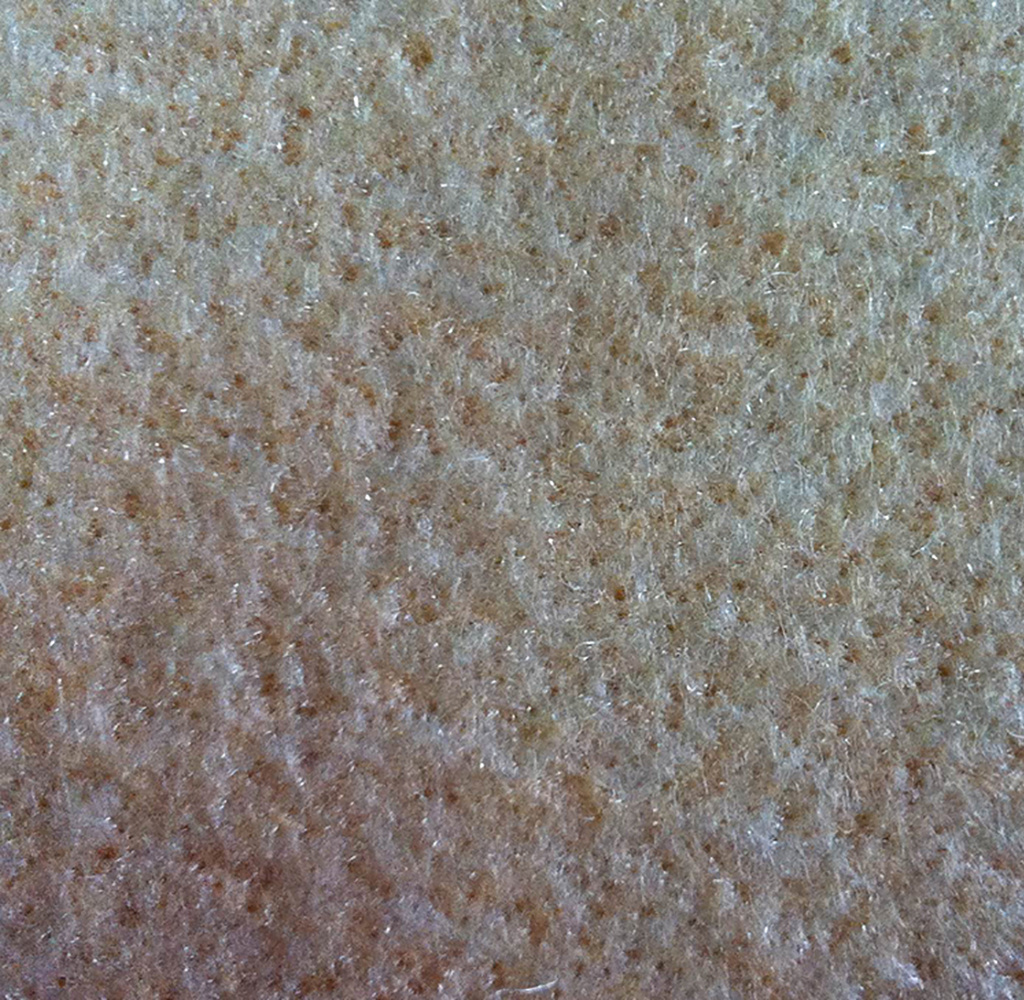

The tissue structure of papermaking felt is set according to different paper machines, different parts of use, and different paper types. The fiber layer is laid in layers with chemical fibers of different thicknesses. It has the characteristics of good water filterability, low elongation, easy washing, light blanket marks, can effectively reduce groove marks, and long service life. It is widely used in various paper machines to produce various papers.

Classification:

Product Description

|

Item |

P.N |

Gram weight |

Structure |

Application |

Note |

|

1 |

17201 |

650—900 |

Single layer |

Suit for cultural,technological, and industrial paper as a blanket |

No blanket printing, fine and uniform blanket surface,good initial adaptability |

|

2 |

17221 |

650—950 |

Single layer |

Suit for cultural,technological, and industrial paper as a blanket |

No blanket printing, fine and uniform blanket surface,good initial adaptability |

|

3 |

37201 |

650—900 |

Single layer |

Suit for cultural,technological, and industrial paper as a blanket |

No blanket printing, fine and uniform blanket surface,good initial adaptability |

|

5 |

37221 |

650—950 |

Single layer |

Suit for cultural,technological, and industrial paper as a blanket |

No blanket printing, fine and uniform blanket surface,good initial adaptability |

|

6 |

17420 |

900—1200 |

Single layer |

Used as blankets to produce special papers such as tissue paper |

No blanket printing, fine and uniform blanket surface,good initial adaptability |

|

7 |

47520 |

1100—1500 |

Double layer |

Used as a press blanket to produce special papers such as technical paper and tissue paper |

No blanket printing, good water filtration, fine and smooth blanket surface, long life |

|

8 |

57350 |

1500— |

Three layer |

Used as a press blanket to produce various special papers, etc. |

No blanket printing, high line pressure resistance, good water filtration, dimensional stability, abrasion resistance, long life |

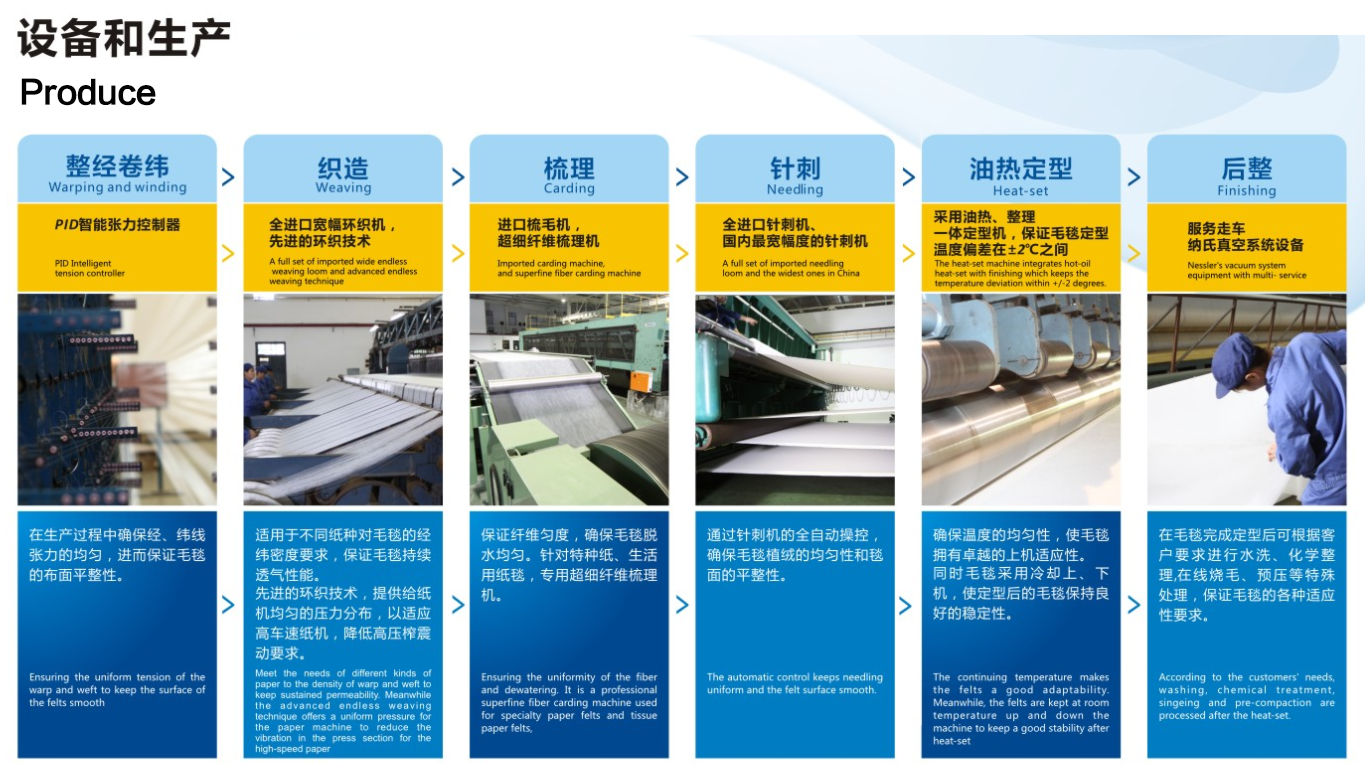

Production Flow

Corrugated cardboard paper making fabric press felt bottom and top paper machine blanket dryer screen for paper industry can also be used as canvas or breathable fabrics made of polyester filament. Papermaking felt divided into woven and knitted. Woven paper making felt using wool and nylon staple fiber blended yarn, blending ratio of about 75:25, by weaving, shrink it, fluff, drying and other processes made of stereotypes. The method of making the papermaking felt is to first fabricate 50% wool and 50% nylon staple fiber or 100% nylon staple fiber into a fibrous web, overlay the layers, and then use a barbed steel needle to staple the web of the annular base fabric, to achieve a certain degree of tightness and flatness. Acupuncture methods are single-sided acupuncture and double-sided acupuncture. Acupuncture blanket with a good water treatment, wear, high strength, long service life characteristics.

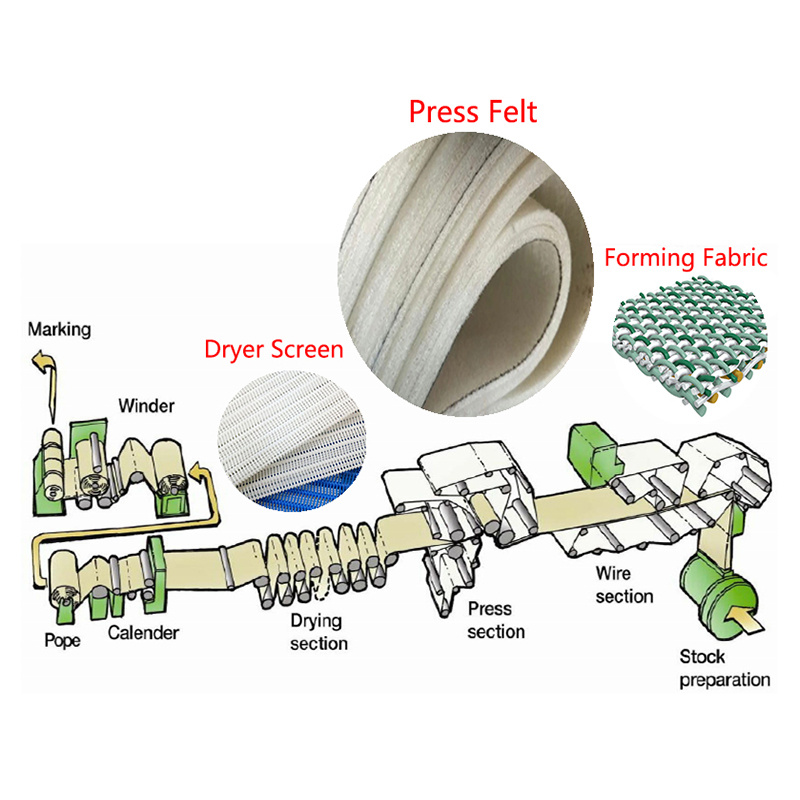

Application

Corrugated cardboard paper making fabric press felt bottom and top paper machine blanket dryer screen for paper industry according to the location in the paper machine can be divided into wet paper making felt, paper making felt and dryer paper making felt. The wet paper making felt is run on the paper machine with the function of squeezing the paper blank so that it is dehydrated and the paper is smooth with high strength, low shrinkage, wear resistance, anti-bacterial and anti-acid corrosion feature . Paper making felt is used above wet paper making felt,connect to the dryer cylinder with small part of paper making felt,with the function of collar paper, top flat and dry .It is smooth, stiff, good elasticity, wear resistance, high temperature performance . Dry paper making felt covered dryer cylinder, running in hot and dry conditions, flat and dried the paper , with a solid, flexible, wear, high temperature performance.

Working shop

Packaging and Delivery

Company Introduction

NH Paper Machinery Industrial Group is a leading professional paper machine manufacturer in China, which specializes in making machine, paper making machine and all kinds of paper machine components manufacturing. Based on the development of local market ,we are growing to professional paper mill solution provider. NH Paper Machinery Industrial Group fully implement the guideline in business-"survival depends on quality and service ,market rely on price and brand."

Our main products are a full set of new and second hand paper making equipment with a maximum net with of 6000mm and a working speed of 700m/min.It mainly includes a packaging paper production line with an annual output of 200,000-200,000 tons, a cultural paper production line with an annual output of 1-10 million tons, a tissue paper production line with an annual output of 20,000 tons and various special paper production lines.

Look forward to hearing from you sooner and establishing a long friendly business relationship with you . We promise we will do our best to help you .Besides ,welcome you to visit our factory at anytime.

We have stable cooperation relationship with our clients.

Key words:

Related Products

Welcome your product consultation

Qinyang NH Paper Machinery Industrial Group Co., Ltd.

WhatsApp/WeChat:Cathy Wang 0086-15721522521

WhatsApp/WeChat:Ailsa Zhao 0086-18300605679

ADD: Jianshe Road(South),Qinyang City Henan Province,China

Cathy Wang

Alisa Zhao

TikTok

Copyright©Qinyang City Nianhai Net Industry Co., Ltd.

SAF Coolest v1.3.1.1 设置面板 AIVSX-ZBBO-FQSEE-ZAS

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page